Table of Contents

- What is a Backorder?

- How does the backordering process function?

- What are the main causes of backorders?

- What is the difference between backorder and out-of-stock?

- How do backorders impact the supply chain?

- How can retailers prevent backorders?

- Conclusion

What is a Backorder?

In retail and inventory management, a backorder refers to a customer order for a product that is currently out of stock but will be restocked soon. Backorders help maintain sales continuity by allowing businesses to accept orders even when inventory is temporarily unavailable. This situation typically arises when high demand exceeds the available supply or when there are supply chain issues for a variety of reasons.

Backorders play a crucial role in an effective retail inventory management strategy for several reasons:

- Retailers preserve sales opportunities despite temporary stockouts, reducing potential revenue loss to competitors and customer dissatisfaction.

- These orders generate valuable demand data, enabling more accurate reorder points and better purchase order decisions.

- Strategic backorder management helps small businesses lower their storage space carrying costs while still meeting customer expectations.

- Tracking backorder patterns reveals product popularity trends and highlights potential supply chain problems requiring attention.

How does the backordering process function?

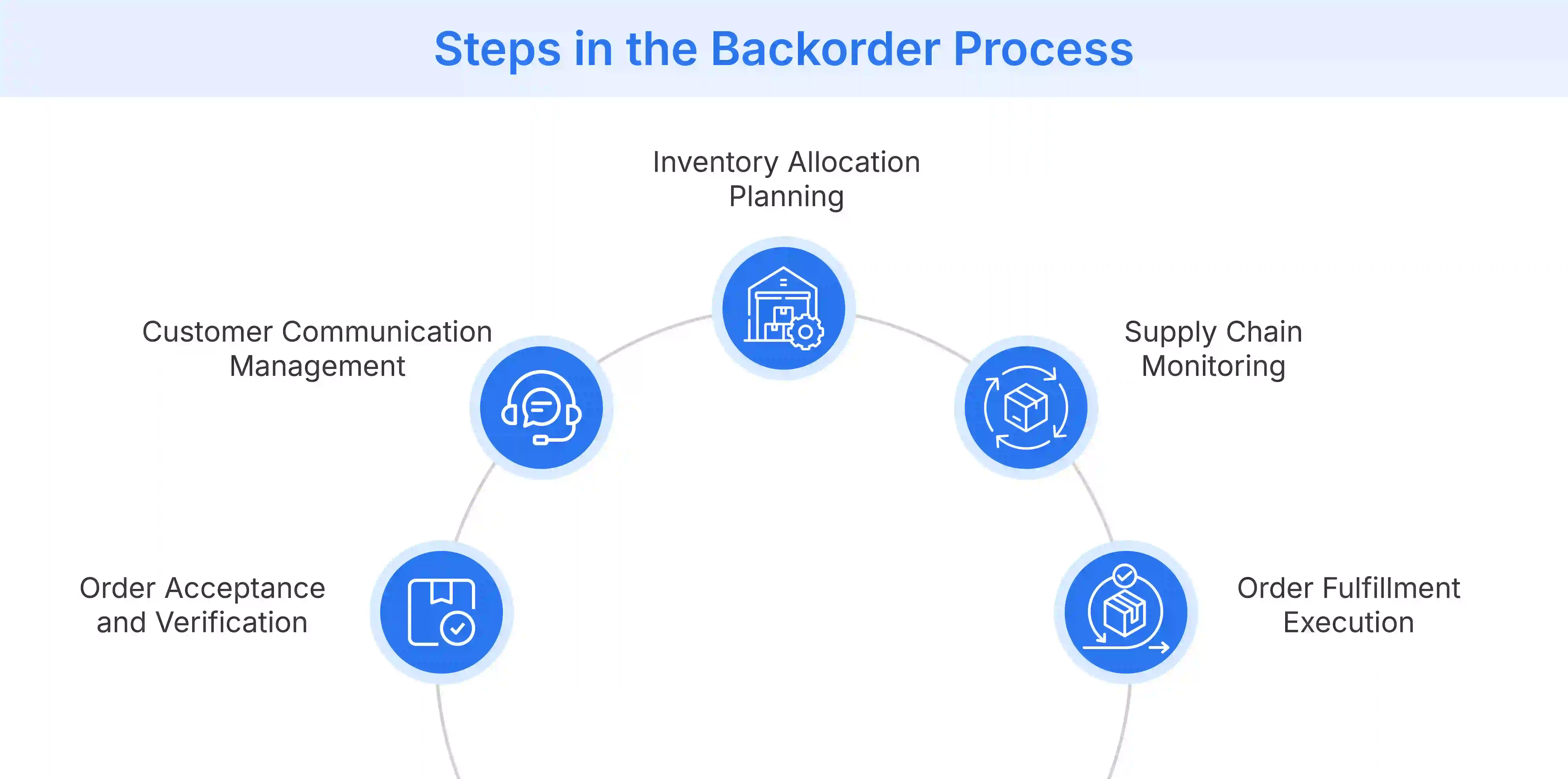

The backorder process involves systematic steps retailers follow when accepting orders for out-of-stock items:

- Order Acceptance and Verification: Retailers’ systems identify inventory status during checkout and flag the item as backordered, confirming with customers that they’re purchasing a product requiring future fulfillment with estimated delivery dates.

- Customer Communication Management: Upon backorder creation, automated systems notify customers about order status, providing realistic timeframes for delivery and setting appropriate expectations to maintain transparency throughout the waiting period.

- Inventory Allocation Planning: When replenishment inventory arrives, retailers allocate stock to backorders chronologically, ensuring first-come-first-served fulfillment while accounting for priority customers and special handling requirements as needed.

- Supply Chain Monitoring: Retailers maintain constant communication with primary suppliers about backordered items, tracking production progress and shipping status to update internal systems and adjust customer delivery estimates accordingly.

- Order Fulfillment Execution: Once inventory becomes available, retailers prioritize backorder fulfillment over new orders, expediting processing and shipping while sending automated notifications about payment information and order progress.

To optimize this critical process, the Order Management System from Flipkart Commerce Cloud (FCC) provides comprehensive backorder support. We streamline the entire workflow through automated processing, exception handling, and real-time inventory visibility across all your locations. Our solution delivers precise delivery estimates, customizable business rules, and seamless integration with your existing inventory and fulfillment systems.

What are the main causes of backorders?

Backorders typically result from several critical factors within retail inventory and supply chain operations:

- Inaccurate Demand Forecasting: Retailers experience backorders when forecasting models fail to account for market trends, competitor actions, or unexpected consumer behavior shifts, resulting in insufficient inventory ordering.

- Supply Chain Disruptions: Negative impact of external factors like natural disasters, transportation delays, labor shortages, or global health crises can interrupt normal supply flows, creating inventory shortages that trigger backorder situations.

- Production Capacity Limitations: Manufacturers sometimes face a shortage of raw materials, equipment breakdowns, or labor constraints that restrict their ability to fulfill retail orders on schedule, necessitating backorder arrangements.

- Seasonal Demand Fluctuations: Holiday rushes, weather-related purchasing spikes, or promotional events can create sudden demand surges that exceed even well-planned inventory levels, leading to temporary backorders.

- Ineffective Inventory Management: Outdated inventory systems, poor stock visibility across locations, inadequate safety stock policies, or delayed reordering processes frequently contribute to preventable backorder situations.

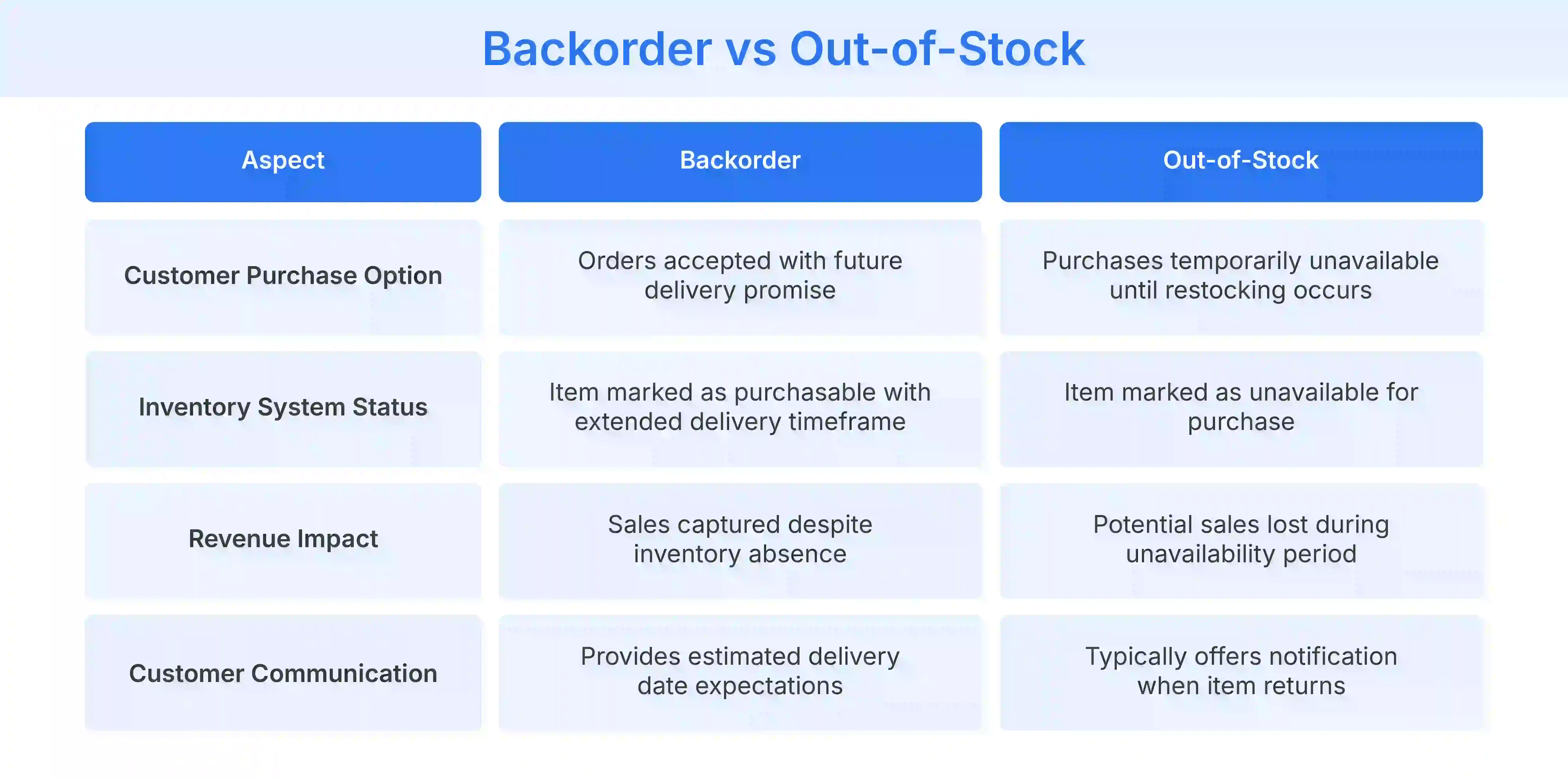

What is the difference between backorder and out-of-stock?

The fundamental difference between backorders and out-of-stock situations involves customer purchasing options. Backordered items remain available for purchase despite current unavailability, with retailers accepting orders for future delivery once stock arrives. Conversely, out-of-stock items cannot be purchased until the retailer restocks and reopens sales.

How do backorders impact the supply chain?

Backorders influence multiple operational areas and can significantly affect overall business efficiency, profitability, and relationship management.

- Increased Operational Complexity: Supply chain managers must establish separate tracking systems and fulfillment processes for backordered items. This creates additional workflow complexity that can strain resources and increase administrative burden.

- Inventory Holding Pattern Disruptions: Backorders force warehouses to hold partial shipments and manage reserved spaces for incoming inventory. This complicates standard storage protocols and potentially creating inefficient space utilization.

- Supplier Relationship Strain: Frequent backorder situations can create tension with suppliers as retailers escalate replenishment requests, demand expedited shipping, and potentially implement penalty clauses for delivery failures.

- Transportation Cost Escalation: Retailers often incur premium shipping charges to expedite backorder fulfillment once inventory arrives. This decreases profit margins while potentially disrupting normal logistics operations and delivery schedules.

- Cash Flow Cycle Alterations: Backorders can create financial complications by extending the time between customer payment collection and order fulfilment. This affects standard accounting procedures and inventory investment calculations.

How can retailers prevent backorders?

Retailers can implement several effective strategies to minimize stockout situations and maintain consistent product availability.

- Implement advanced demand forecasting that incorporates historical data, market trends, and shipping delays to predict inventory needs.

- Establish appropriate safety stock levels based on sales velocity, supplier reliability, and the product’s strategic importance. This is crucial to mitigate low safety stock risks.

- Develop strong supplier partnerships with clear communication channels and performance metrics for consistent inventory replenishment.

- Deploy automated inventory management systems that provide real-time stock visibility across all sales channels and locations.

- Create standardized stockout response protocols that immediately trigger reordering processes when inventory reaches threshold levels.

- Analyze sales patterns to identify common backorder triggers and adjust purchasing parameters for problematic product categories.

- Consider alternative fulfillment methods like dropshipping or vendor-managed inventory for products with consistent availability challenges.

- Implement robust mechanisms for supply chain delays that identify potential disruptions before they impact product availability.

Conclusion

Backorders represent a great way to balance customer loyalty with operational efficiency. When properly implemented, backorder systems help retailers capture sales that would otherwise be lost while providing transparent delivery expectations to customers. When properly implemented, backorder systems help retailers capture sales that would otherwise be lost while providing transparent delivery expectations to customers.

Effective backorder management requires robust inventory systems, clear communication protocols, and strong supplier relationships. Retailers who master this balance can maintain leaner inventory levels while still meeting customer demands, ultimately improving cash flow and reducing carrying costs.

By continuously analyzing backorder patterns, businesses can identify opportunities to refine forecasting accuracy, strengthen supply chain resilience, and enhance the overall customer experience despite temporary inventory gaps.

FAQ

Backorder fulfillment times vary, with most retail backorders fulfilled within 2-4 weeks. The number of backorders and first-time customer experiences depends on the timely manner of fulfillment and the right inventory management. Retailers should maintain regular communication with suppliers to provide customers with accurate delivery timeframes.

Most retailers process payments for backordered items differently from in-stock purchases. Some collect payment at order placement to secure inventory allocation, while others charge only when shipping occurs. Many retailers offer flexible cancellation policies for backorders, allowing customers to withdraw if estimated delivery dates extend too far.

Backorders occur frequently in e-commerce due to the channel’s unlimited virtual shelf space and broad product catalogs. Online retailers often maintain smaller physical inventories while offering wider selections, increasing backorders. E-commerce platforms typically incorporate specific backorder functionality, including automated customer notifications and delivery date estimations.