Table of Contents

- What is Inventory Control?

- What are the Different Ways to Control Inventory?

- How Does Inventory Control Differ from Inventory Management?

- What Causes Dead Stock and How Can it Be Eliminated?

- What Types of Inventory Control Systems are Available?

- What are the Key Metrics in Inventory Control?

- What Challenges Do Businesses Face with Inventory Control?

- How is Technology Transforming Inventory Control?

What is Inventory Control?

Inventory control is a systematic approach to managing stock levels and product availability within a business. It involves tracking, regulating, and optimizing the quantity and quality of goods throughout the supply chain. This process ensures that you have the right amount of inventory at the right time to meet customer demand without tying up excessive capital in stock.

Effective inventory control helps you balance the competing needs of minimizing holding costs and maximizing customer satisfaction. By implementing robust inventory control measures, you can reduce the risk of stockouts, overstocking, and obsolescence. This, in turn, leads to improved cash flow, increased profitability, and enhanced operational efficiency.

What are the Different Ways to Control Inventory?

Inventory control methods have evolved from traditional manual approaches to advanced digital solutions, each offering unique advantages for businesses of various sizes and complexities.

- Manual Inventory Control: This traditional method involves physical counting and recording of stock levels. It is suitable for small businesses with limited product lines, offering a tangible understanding of inventory levels. Regular stock checks, manual record updates, and reorder point calculations are essential components of this hands-on approach.

- Stock Cards: A more organized manual system, stock cards involve creating individual cards for each product. These cards record crucial details like quantity, location, and reorder levels. This method offers quick reference and visual representation of inventory status, making it particularly useful in smaller warehouses or retail settings.

- Simple Spreadsheets: Leveraging basic software like Microsoft Excel or Google Sheets, this method enables easy updates, basic calculations, and simple data analysis. It is a step up from manual methods, offering improved accuracy and efficiency for small to medium-sized businesses while maintaining flexibility and customization options.

- Inventory Software: For complex inventory management needs, Flipkart Commerce Cloud offers advanced solutions. We provide advanced features, including real-time inventory visibility, automated reordering, and predictive analytics. Our system integrates seamlessly with other business processes, offering a holistic approach to inventory control for growing businesses and large enterprises.

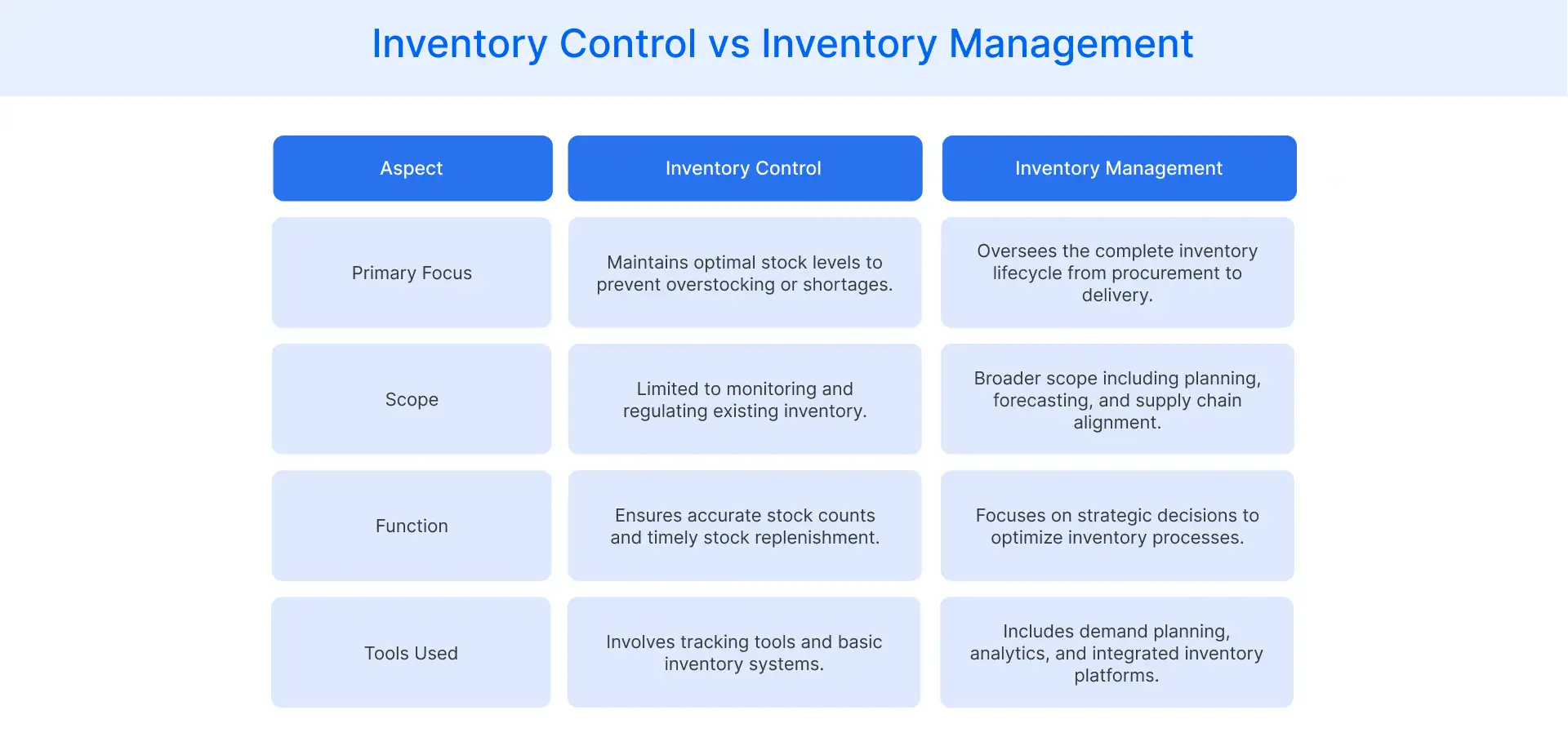

How Does Inventory Control Differ from Inventory Management?

While often used interchangeably, inventory control and inventory management serve distinct but complementary roles in a supply chain strategy.

Inventory control focuses on the day-to-day operations of maintaining optimal stock levels within your warehouse or storage facility. It involves tracking, monitoring, and adjusting inventory to prevent understocking and overstocking.

In contrast, inventory management encompasses a broader scope, overseeing the entire lifecycle of your inventory from procurement to distribution. It involves strategic decision-making about sourcing, production planning, and supply chain optimization.

Both processes aim to optimize inventory levels, improve operational efficiency, and meet customer demand promptly. They share common tools, such as specialized software for tracking and analytics. However, inventory management systems are typically more complex, incorporating features like demand forecasting and multi-location management.

What Causes Dead Stock and How Can it Be Eliminated?

Dead stock refers to items that have not sold for an extended period. Understanding its causes and implementing effective elimination strategies can significantly improve your inventory management efficiency:

- Overstocking: Excessive inventory often results from inaccurate demand forecasting or bulk purchase decisions. To address this, implement data-driven forecasting methods and consider just-in-time inventory practices. Regularly review your stock levels and adjust your ordering patterns based on actual sales data and market trends.

- Poor Product Quality: Substandard products can lead to customer returns and unsold inventory. Enhance your quality control processes and work closely with suppliers to ensure consistent product standards. Consider implementing a robust return policy and use customer feedback to improve product offerings.

- Seasonal Fluctuations: Seasonal items can quickly become dead stock if not sold during their peak period. Plan your inventory control strategy around seasonal trends, using historical data to predict demand. Implement early markdown strategies for seasonal items and consider pre-season sales to gauge customer interest.

- Ineffective Marketing: Products may become dead stock due to inadequate promotion or positioning. Develop targeted marketing campaigns to highlight slow-moving items. Utilize product bundling strategies by combining slow-moving items with popular products to enhance their visibility and increase customer appeal.

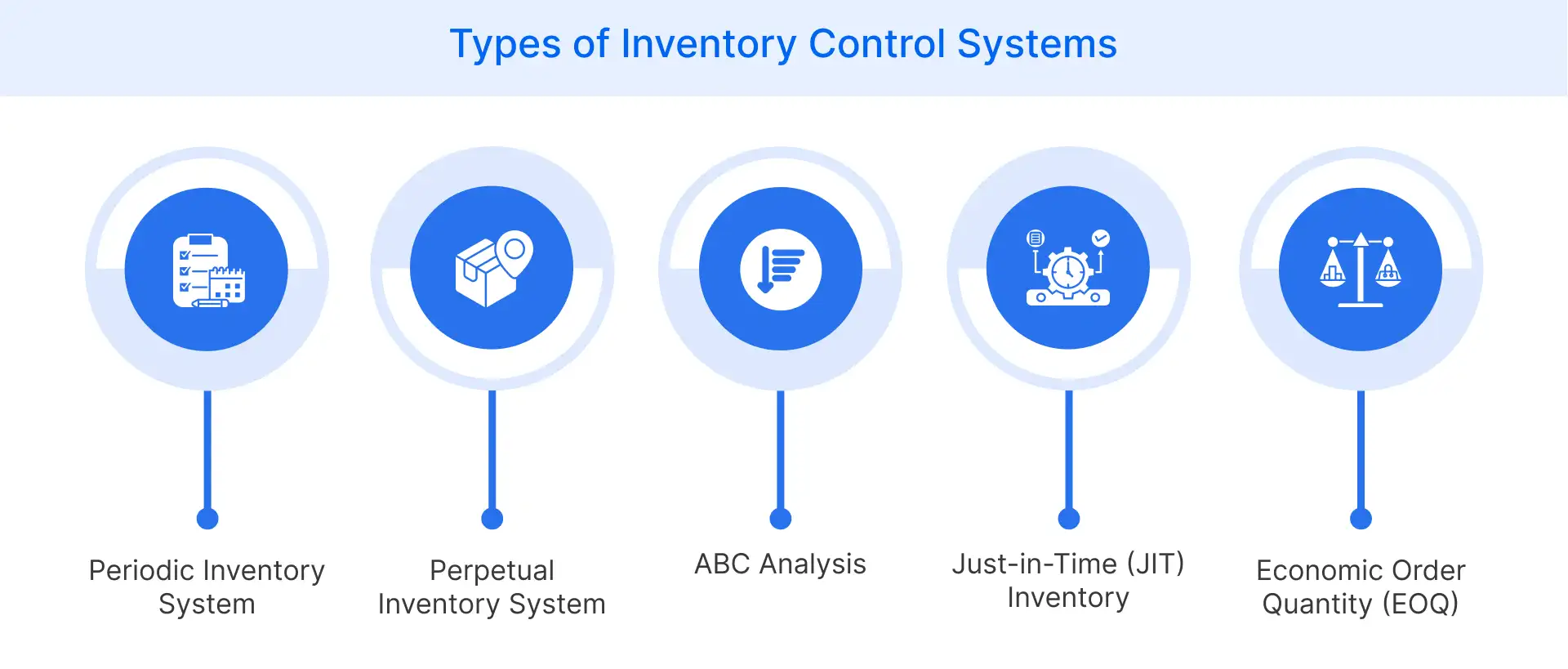

What Types of Inventory Control Systems are Available?

Effective inventory control relies on various methodologies, each tailored to specific business needs and operational contexts.

Periodic Inventory System

In this system, you conduct physical inventory counts at set intervals, such as monthly or quarterly. It is well-suited for smaller businesses with lower sales volumes or those dealing with less perishable goods. While it requires less day-to-day record-keeping, it may lead to temporary stock inaccuracies between counts. This system can be cost-effective but requires careful timing to avoid disruptions.

Perpetual Inventory System

This modern approach involves real-time tracking of inventory levels, often using barcode scanners or RFID technology. It is ideal for businesses with high transaction volumes or those requiring precise stock control. You will benefit from up-to-date inventory information, enabling quicker decision-making and reducing the risk of stockouts. However, it requires a higher initial investment in technology and staff training.

ABC Analysis

This method categorizes your inventory items based on their value and importance to your business. ‘A’ items are high-value products requiring close monitoring, ‘B’ items are moderately valuable, and ‘C’ items are low-value products. By prioritizing your inventory control efforts, you can allocate resources more efficiently, focusing on items that have a significant impact on your bottom line.

Just-in-Time (JIT) Inventory

JIT aims to minimize inventory levels by coordinating demand and supply chains precisely. You receive stock only when it is needed for production or sales, reducing carrying costs and the risk of obsolescence. This system requires excellent supplier relationships and accurate demand forecasting. It’s particularly effective in manufacturing settings but can be adapted for retail environments.

Economic Order Quantity (EOQ)

EOQ is a calculation method to determine the optimal order quantity that minimizes total inventory costs. It balances ordering costs against carrying costs to find the most economical order size. By implementing EOQ, you can reduce overall inventory expenses and improve cash flow. However, it assumes constant demand and fixed costs, which may not always reflect real-world conditions.

What are the Key Metrics in Inventory Control?

Tracking Key Performance Indicators (KPIs) helps you assess how efficiently your inventory control processes support business goals:

- Inventory Turnover Ratio shows how often inventory is sold and replenished. A higher ratio indicates strong sales performance and efficient stock movement.

- Sell-Through Rate measures the percentage of inventory sold against the total received. It helps identify product performance and adjust purchasing decisions.

- Days of Inventory on Hand (DOH) reveals how many days your current inventory will last. Lower values reflect better stock rotation and tighter inventory control.

- Stockout Rate indicates how frequently products are unavailable. A high stockout rate indicates poor planning and negatively impacts customer satisfaction levels.

- Carrying Cost of Inventory measures the total cost of holding inventory, including storage, insurance, and depreciation. Lower costs suggest more efficient inventory control.

- Rate of Return shows the percentage of sold items returned by customers. High return rates may highlight quality or inventory selection issues.

What Challenges Do Businesses Face with Inventory Control?

Effective inventory control is crucial for business success, but it comes with its share of challenges.

- Demand Forecasting Inaccuracies: Predicting future demand is complex due to market fluctuations, seasonal changes, and unexpected events. Inaccurate forecasts can lead to overstocking or stockouts, which in turn impact your cash flow and customer satisfaction.

- Manual Tracking Errors: Relying on manual processes for inventory tracking increases the risk of human errors. These mistakes can lead to inventory discrepancies, which in turn affect your decision-making and operational efficiency.

- Supply Chain Complexities: Managing inventory across multiple locations or dealing with numerous suppliers can complicate your inventory control efforts. Coordinating deliveries, maintaining consistent stock levels, and ensuring timely replenishment become more challenging

- Balancing Inventory Levels: Striking the right balance between having enough stock to meet demand and avoiding excess inventory is a constant challenge. Overstocking ties up capital and increases carrying costs, while understocking can lead to lost sales.

How is Technology Transforming Inventory Control?

Modern technology has streamlined inventory control by introducing advanced solutions that enhance efficiency and scalability in managing stock levels. Automated systems now enable real-time tracking, predictive analytics, and seamless integration across various business operations, reducing human error and optimizing supply chain performance.

At Flipkart Commerce Cloud (FCC), we offer a comprehensive suite of tools designed to empower retailers in this technological evolution. Our Warehouse Management System (WMS) streamlines warehouse operations by providing precise stock management, reducing errors, and lowering operational costs. It facilitates faster shipping from multiple inventory locations, ensuring timely order fulfillment.

Our Supply Chain Management Software offers modular solutions that integrate various facets of the supply chain, enhancing visibility and coordination. This integration allows retailers to make informed decisions, improve demand forecasting, and maintain optimal inventory levels.

FAQ

Demand forecasting is crucial in inventory control, helping businesses predict future product requirements. It enables you to optimize stock levels, prevent overstocking or understocking, and align inventory with anticipated customer demand. Accurate forecasting reduces waste, improves customer satisfaction, and enhances overall operational efficiency.

Effective inventory control directly impacts operational costs by minimizing excess stock, reducing storage expenses, and preventing stockouts. By optimizing inventory levels, businesses can lower carrying costs, minimize waste, and improve cash flow. Implementing advanced inventory control strategies can lead to significant cost savings.

The frequency of physical inventory counts depends on your business type and industry. Retail businesses typically conduct counts quarterly or annually, while high-volume industries might perform monthly checks. The goal is to balance accuracy with operational efficiency, using technology to minimize disruptions.

While often used interchangeably, inventory control is a more comprehensive approach to managing inventory. Stock control primarily focuses on tracking physical stock quantities, whereas inventory control encompasses broader strategic elements like demand forecasting, order optimization, and effective inventory management.