Table of Contents

- What is Just In Time Delivery?

- Key Principles of Just-In-Time Delivery

- How Just-in-Time Delivery Works

- Advantages of Just-in-Time Delivery

- Disadvantages of Just-in-Time Delivery

- Just-in-Time Delivery vs. Traditional Inventory Management

- Best Practices for Effective Just-in-Time Delivery

- Conclusion

What is Just-in-Time Delivery?

Just-in-Time (JIT) delivery is an inventory management strategy that ensures raw materials, components, and finished goods arrive precisely when needed on the production floor or in the sales process. This approach helps businesses minimize storage costs, decrease waste, and improve operational efficiency by delivering inventory in response to real-time demand rather than maintaining large stock levels.

By aligning production cycles with customer orders, the JIT production system helps businesses optimize their inventory turnover and free up capital that would otherwise be tied to excess stock. The strategy relies on accurate demand forecasting, streamlined logistics, and reliable supply chain companies to ensure uninterrupted operations.

JIT inventory system is particularly beneficial in industries like retail, manufacturing, and automotive, where lead times, supply chain agility and cost control are critical. When implemented effectively, this method enhances responsiveness to market changes while maintaining lean operations, ultimately improving profitability and customer satisfaction.

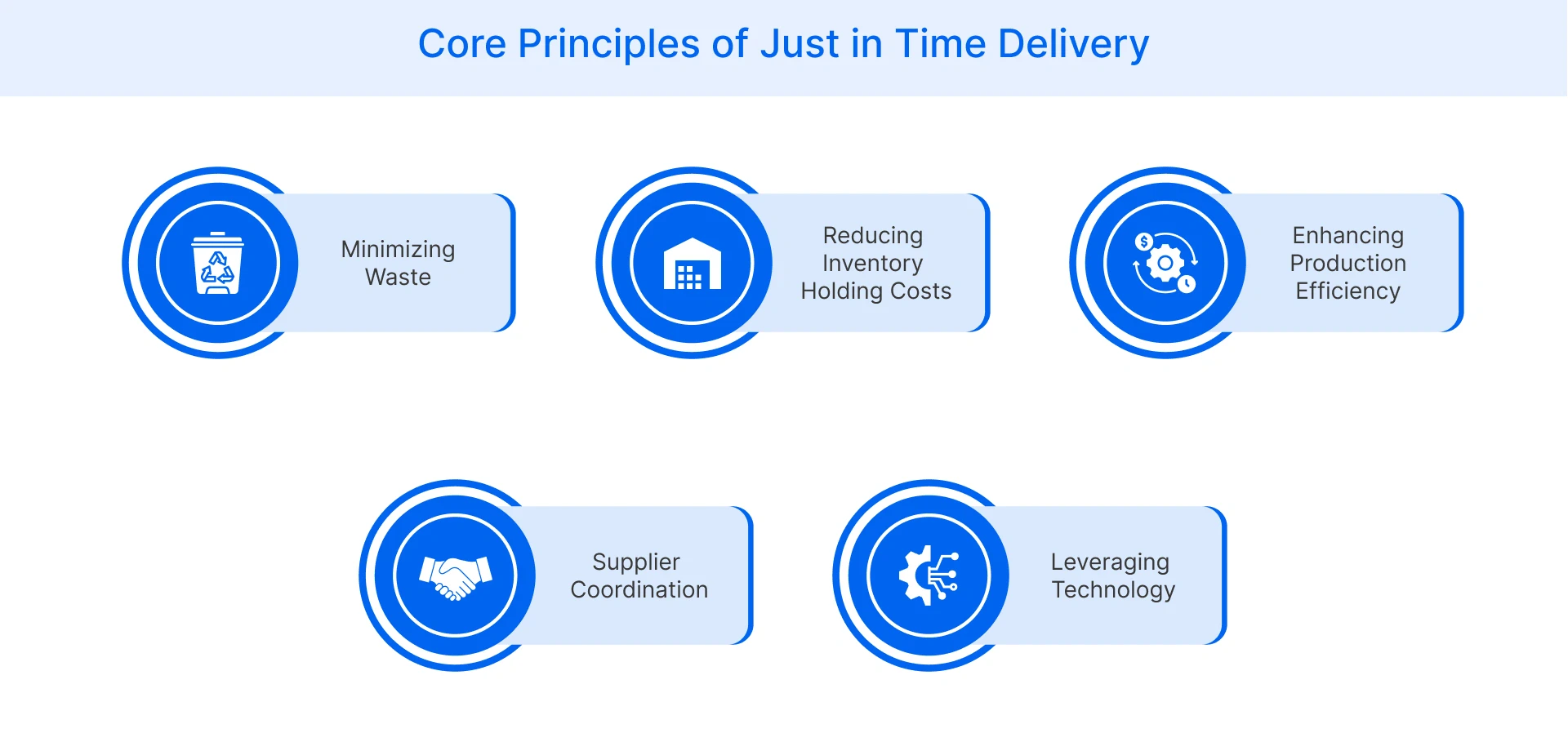

Key Principles of Just-In-Time Delivery

Just-in-Time (JIT) delivery is founded on the following principles that guide its implementation:

- Minimizing Waste: JIT inventory management focuses on eliminating waste by ensuring that materials arrive only when needed, reducing unsold inventory and overproduction. This minimizes warehouse space requirements and decreases the risk of obsolescence by ensuring faster delivery.

- Reducing Inventory Holding Costs: By maintaining minimal inventory levels, JIT delivery significantly lowers the costs associated with storing and managing inventory. This frees up capital that can be used for other business operations.

- Enhancing Production Efficiency: JIT delivery aims to synchronize production runs with customer demand, ensuring that each component is available precisely when required. This reduces downtime and enhances overall production efficiency.

- Supplier Coordination: Effective JIT delivery requires strong relationships and seamless communication with suppliers. This ensures timely deliveries and reduces the likelihood of supply chain disruptions.

- Leveraging Technology: The use of order fulfillment systems, AI, automation, and supply chain management software, is crucial in JIT delivery. These tools help monitor inventory levels, predict demand, and optimize delivery schedules, ensuring accuracy and efficiency in the process.

How Just-in-Time Delivery Works?

Just-in-Time (JIT) delivery relies on the following fundamental components to ensure efficiency and precision:

Inventory Management and Demand Forecasting

Effective JIT delivery starts with real-time inventory management and accurate demand forecasting. By continually tracking the quantity of inventory and predicting demand, supply chain management companies can ensure that stock arrives exactly when needed. This minimizes excess inventory, reduces holding costs, and enhances operational efficiency. Precise demand forecasting is essential to prevent stockouts and overstock situations, ensuring a smooth production flow.

Supplier Coordination and Logistics

Suppliers play a critical role in maintaining a seamless JIT process. Close collaboration with suppliers ensures greater control over lead times, reducing the risk of supply chain disruptions at any given moment. Efficient logistics are essential to transport materials quickly and reliably, keeping the production process running smoothly. Establishing strong relationships with reliable suppliers and utilizing effective communication channels are key to the success of JIT delivery.

Role of Technology in Just-in-Time Delivery

Technology is a key enabler of JIT delivery. AI, automation, lean manufacturing tools, and supply chain management software help streamline processes and ensure accuracy. These tools monitor inventory levels, optimize delivery schedules, and provide real-time insights, enhancing the overall efficiency of the JIT system. Implementing functional production cells helps reduce human errors, improve quality control, and improve the precision of inventory management and supplier coordination.

Advantages of Just-in-Time Delivery

Just-in-Time (JIT) delivery offers several advantages that can significantly enhance your retail operations. Here are the key benefits of JIT available for a wide range of industries:

- Reduced Inventory Costs: JIT delivery minimizes the need for large storage spaces by ensuring that goods arrive exactly when needed. This helps lower inventory holding costs.

- Improved Cash Flow: By reducing the amount of capital tied up in inventory, JIT delivery frees up funds for other business activities, improving your cash flow and financial flexibility.

- Minimal Waste: JIT delivery reduces waste by minimizing overproduction and excess inventory. This leads to more efficient use of resources and lower disposal costs.

- Higher Operational Efficiency: With JIT delivery, you can synchronize production with demand, reducing downtime and ensuring that operations run smoothly and efficiently.

Disadvantages of Just-in-Time Delivery

While Just-in-Time (JIT) delivery has many benefits, it also comes with potential drawbacks:

- Supply Chain Disruptions: JIT delivery relies heavily on timely deliveries. Any disruptions in the supply chain, such as delays or transportation issues, can lead to significant production delays.

- Dependency on Reliable Suppliers: JIT delivery requires strong, reliable relationships with suppliers. If suppliers fail to deliver on time, it can disrupt the entire production process.

- Risk of Stockouts: With minimal inventory levels, there's an increased risk of stockouts. If demand unexpectedly spikes or delivery delays occur, it can lead to lost sales and dissatisfied customers.

- Limited Buffer for Emergencies: JIT delivery offers little room for errors or emergencies. Any unforeseen events, such as natural disasters or supplier issues, can severely impact operations due to the lack of safety stock.

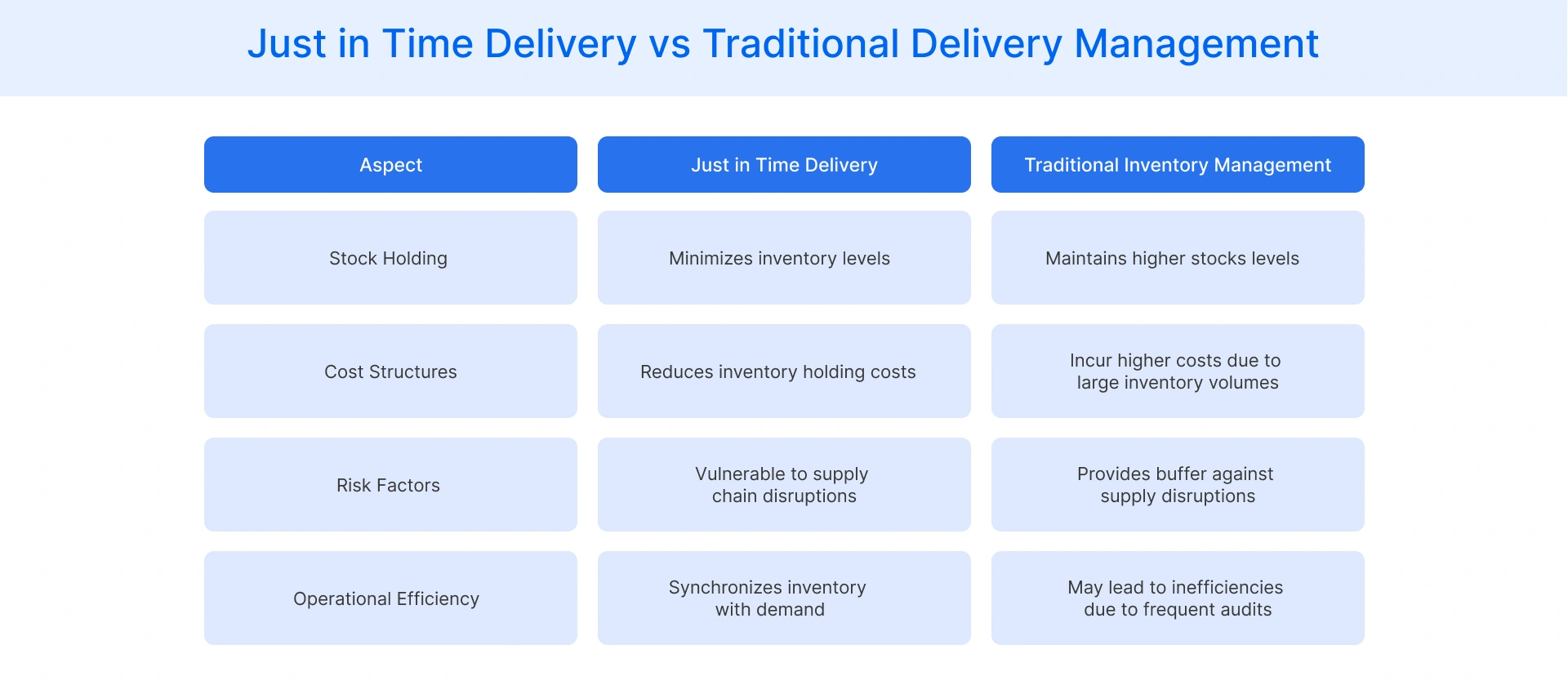

Just-in-Time Delivery vs. Traditional Inventory Management

Just-in-Time (JIT) delivery and traditional inventory management represent two distinct approaches to managing stock. Here are the key differences between them:

- Stock Holding: JIT delivery minimizes inventory levels by coordinating deliveries to match production schedules, reducing the need for large storage spaces. In contrast, traditional inventory control maintains higher stock levels to buffer against demand fluctuations and supply chain delays.

- Cost Structures: With JIT delivery, you can significantly reduce inventory holding costs by minimizing excess stock. This leads to lower warehousing expenses and improved cash flow. Traditional inventory management, however, incurs higher costs due to larger inventory volumes and the need for extensive storage facilities.

- Risk Factors: JIT delivery relies on precise timing and robust supplier relationships to ensure timely deliveries. This reduces the risk of overstocking but increases vulnerability to supply chain disruptions and stockouts. Traditional inventory management provides a buffer against such disruptions but may result in overproduction and waste due to excess inventory.

- Operational Efficiency: JIT delivery enhances production efficiency by synchronizing inventory with demand, reducing downtime, and enabling a leaner operation. Traditional inventory management, while providing more stability, may lead to inefficiencies due to the need for frequent inventory audits and adjustments.

Best Practices for Effective Just-in-Time Delivery

Implementing just-in-time delivery successfully requires a strategic approach that enhances operational efficiency and minimizes supply chain risks. One crucial best practice is fostering strong supplier partnerships to ensure timely deliveries. Open communication, performance tracking, and long-term contracts help secure reliable material flow, reducing the risk of disruptions.

Inventory automation plays a vital role in optimizing JIT delivery. By adopting real-time tracking systems, businesses can monitor stock levels accurately, reduce manual errors, and improve demand forecasting. At Flipkart Commerce Cloud (FCC), we offer advanced inventory management solutions that provide real-time visibility into stock movements, helping avoid overstocking or stockouts.

Another key practice is contingency planning to address potential supply chain disruptions. Preparing for unforeseen challenges with FCC’s supply chain management solutions ensures continuity in operations.

Integrating advanced technologies such as AI-driven analytics and IoT sensors enhances inventory flow and demand prediction. At FCC, we support these efforts with our AI-powered demand forecasting tools, enabling you to respond proactively to changing market conditions.

Conclusion

Just-in-Time (JIT) delivery can significantly optimize flow of goods by reducing dead stock and minimizing waste. Effective planning and strong supplier coordination are essential for its success. Implementing JIT delivery improves operational efficiency, enhances cash flow, and ensures timely replenishment of inventory. With a reliable partner like Flipkart Commerce Cloud, you can implement JIT delivery effectively, ensuring timely inventory flow and long-term supply chain success.

FAQ

JIT delivery focuses on minimizing inventory by receiving goods just before they are needed for production or sale. Drop shipping involves retailers shipping products directly from suppliers to customers, bypassing inventory storage and reducing handling costs.

JIT delivery in global supply chains faces risks such as supply chain disruptions, dependency on reliable suppliers, and increased vulnerability to transportation delays. These risks can lead to stockouts and production delays.

Just-in-Time (JIT) delivery enhances supply chain efficiency by reducing inventory holding costs, minimizing waste, and ensuring timely replenishment. It synchronizes production schedules with demand, reducing downtime and improving operational flow.