Table of Contents

- What is Order Processing?

- Types of Order Processing Systems

- What are the Steps Involved in Order Processing?

- Challenges of Order Processing

- Best Practices to Manage Efficient Order Processing

- What are the Key Order Processing Performance Metrics?

- Role of Technology in Modern Order Processing

- Conclusion

What is Order Processing?

Order processing is the systematic method for managing customer orders from placement through delivery. It involves capturing order details, verifying information, and coordinating fulfillment across teams. You depend on the order fulfillment process to integrate sales, inventory, and shipping operations to ensure accurate and timely order completion.

Efficient order management process is vital in e-commerce, retail, and logistics. By keeping every part of your operation aligned and informed, you can reduce errors and minimize delays to enhance customer satisfaction.

Efficient order processing offers several key benefits to retail enterprises:

- Accurate sales order processing helps maintain optimal stock levels, reducing the risk of overstocking or stockouts.

- Streamlined processes reduce errors and save time, allowing your team to handle more orders with fewer resources.

- Efficient order processing can lead to faster payments and improved financial forecasting.

- The data gathered during order processing can provide crucial insights related to popular products and operational bottlenecks.

- A well-designed order processing system can easily accommodate business growth and handle increased order volumes.

Types of Order Processing Systems

Here are the main types of order processing systems that offer varied approaches to managing your orders:

Manual Order Processing

Manual order processing is a traditional approach in which each order is handled individually. Customer details are recorded using spreadsheets or paper forms, and orders are verified by hand. This method suits small businesses but increases the risk of human error and delays when processing high order volumes.

Pros

- Manual processes require minimal initial investment, making it accessible for small businesses with limited budgets.

- You can easily handle unique or complex orders that may require special attention or customization.

Cons:

- Manual processing is time-consuming and labor-intensive, potentially leading to slower fulfillment times for customers.

- There is a higher risk of human errors in data entry, picking or packing, which can result in customer dissatisfaction.

Automated Order Processing

Automated order processing employs dedicated software to capture, verify, and manage orders with limited manual intervention. In this method, you use integrated digital tools to automate data entry, inventory checks, and status updates.

Pros

- Real-time inventory updates help prevent overselling and improve stock management across multiple sales channels.

- Automation significantly reduces processing time, allowing you to handle more orders in less time.

Cons

- You need to invest in software solutions and address integration with legacy systems to streamline the order process.

- Ongoing updates and technical support are necessary to maintain system performance.

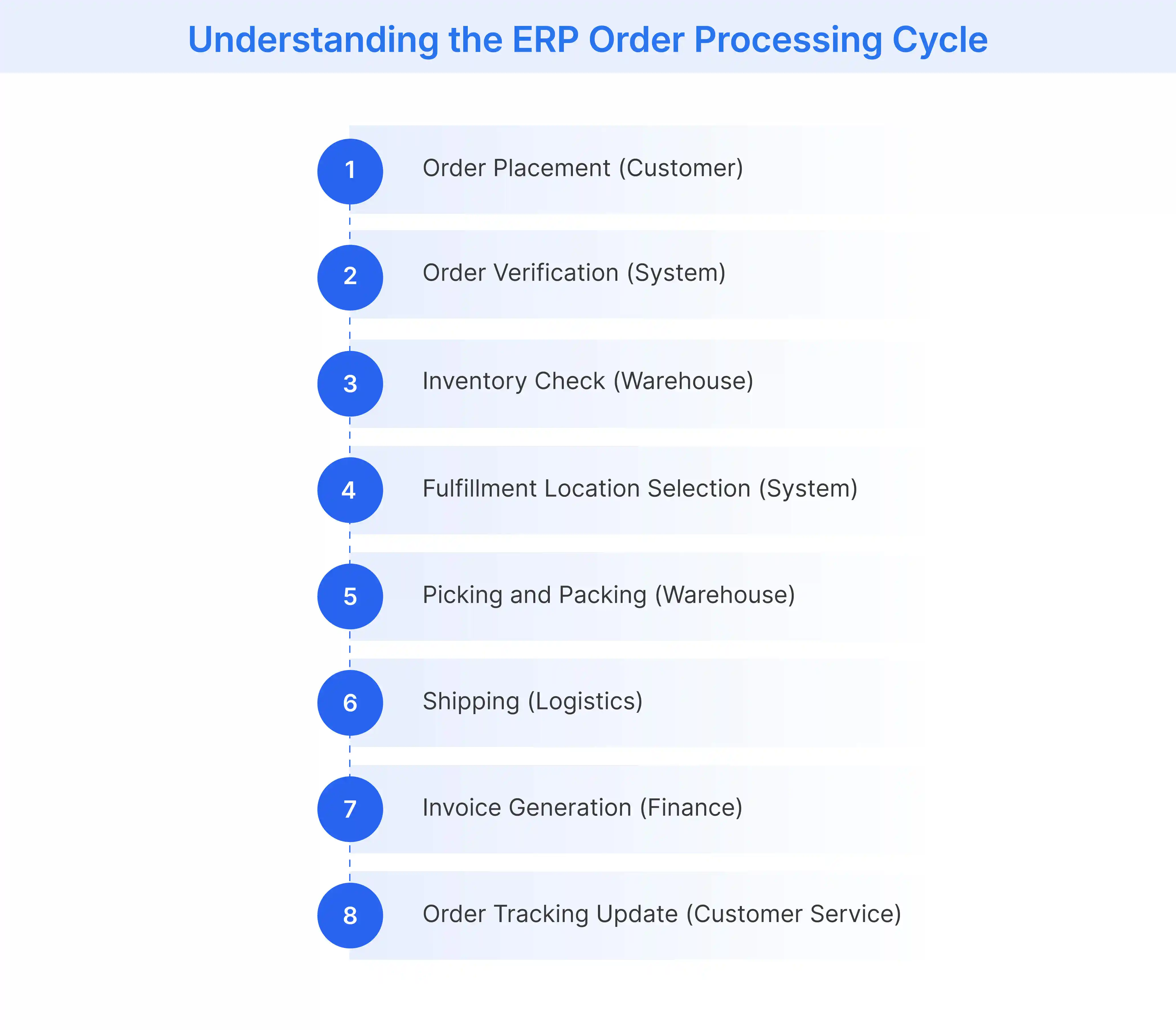

Enterprise Resource Planning (ERP) Order Processing

ERP order processing centralizes your order management by linking sales, inventory, accounting, and logistics into one system. You gain comprehensive visibility and real-time insights across your business that allows efficient handling of high order volumes.

Let’s consider an example to understand the entire process better. A large retail chain implements an ERP system to manage its order processing. The system automatically updates inventory levels across all stores when an online order is placed. It then identifies the optimal fulfillment location based on proximity and stock availability. The order details are sent directly to the warehouse staff for picking and packing while simultaneously updating the finance department for invoicing and the customer service team for order tracking.

Pros

- ERP systems seamlessly integrate order processing with other departments, improving overall operational efficiency.

- You gain access to real-time data and analytics, enabling more informed decision-making across your organization.

Cons

- Implementation is complex, requiring significant resources and comprehensive staff training.

- Continuous maintenance and periodic system updates are essential to ensure effectiveness.

What are the Steps Involved in Order Processing?

Effective order processing requires a structured series of steps to ensure smooth and error-free fulfillment. Here are the different stages involved in order processing:

- Order Placement: During order placement, you capture essential customer details through various channels such as online platforms, in-store systems, or telephone orders. You record product information, payment methods, and delivery instructions accurately. This step of the process initiates the order workflow and sets the stage for subsequent actions.

- Order Confirmation and Verification: After receiving the order, you confirm the details and verify customer information. You validate payment transactions, shipping addresses, and product selections. This careful verification prevents errors and fraudulent activities, ensuring that you proceed confidently through the order processing workflow while maintaining data accuracy and service reliability. You then send an order confirmation to the customer, reassuring them that their request is being processed.

- Inventory Check and Allocation: nce the order is confirmed, you check your inventory to ensure the requested items are in stock. If available, you allocate the products to the order, updating your inventory management software to reflect the change in stock levels.

- Order Picking and Packing: With inventory allocated, warehouse staff locate and retrieve the ordered items from storage. They carefully select each product and verify it against order details before securely packing them using quality materials. This method minimizes damage during transit and ensures that each package is ready for delivery.

- Shipping and Delivery: After packing, you select the appropriate shipping method based on customer preferences or company policies. You generate shipping labels, schedule pickups with carriers, and prepare the necessary documentation for the order's smooth transportation to its destination.

- Order Tracking and Final Confirmation: As the order ships, you provide tracking information to the customer, allowing them to monitor the progress of their package. Upon successful delivery, you send a final confirmation, closing the order processing cycle and opening avenues for post-purchase follow-ups.

Challenges of Order Processing

Order processing comes with several challenges that can impact your business efficiency and customer satisfaction. Here are some key issues you may encounter:

- Order Errors and Inaccuracies: Mistakes in order processing can lead to incorrect shipments, disappointing customers and increasing return rates. These errors often stem from manual data entry, poor inventory management, or inadequate staff training. You may face issues like picking the wrong items or shipping incomplete orders, which can damage your brand reputation.

- Inventory Stockouts: Stockouts occur when you cannot fulfill customer orders due to insufficient inventory. This situation can result in lost sales, frustrated customers, and potential damage to your brand loyalty. Robust inventory management systems and accurate demand forecasting are essential to mitigate this challenge.

- Returns and Refunds Management: The returns process involves multiple steps, from initiating the return request to inspecting the product and processing refunds or exchanges. Mishandling returns can lead to customer dissatisfaction and increased operational costs.

- Handling High Order Volumes During Peak Seasons: During busy periods, you may struggle to manage increased order volumes effectively. This challenge can strain your resources, leading to delays, errors, and customer disappointment. Without proper strategies and systems in place, high-volume periods can overwhelm your order processing capabilities and impact overall business performance.

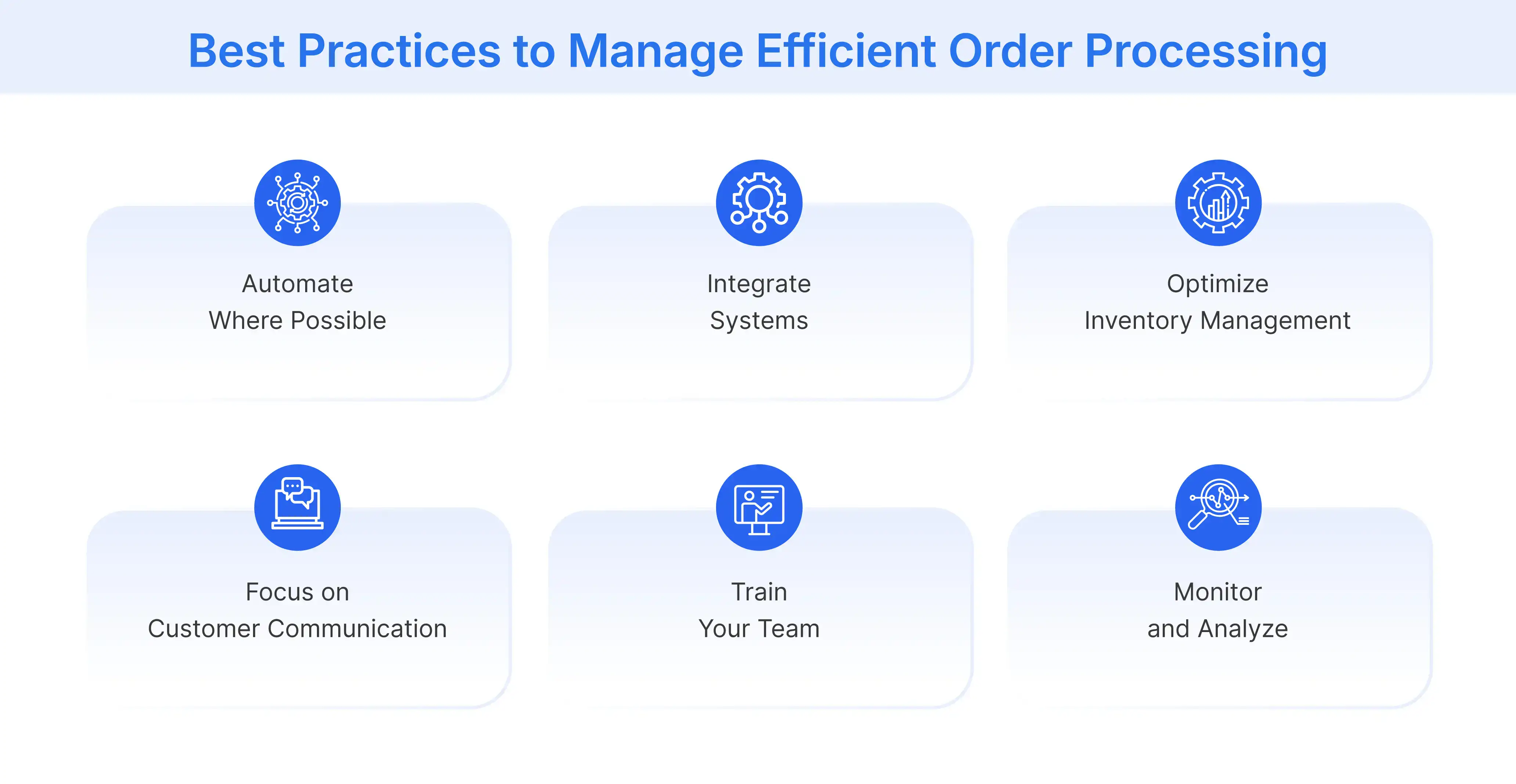

Best Practices to Manage Efficient Order Processing

To optimize your order processing workflow, consider implementing these best practices:

- Automate Where Possible: Leverage software solutions to streamline repetitive tasks. For example, automated order confirmation emails can notify customers instantly when their order is received. This reduces manual work and minimizes communication errors. Flipkart Commerce Cloud’s (FCC) specialized retail solutions can automate various aspects of order processing, from fraud detection to pricing optimization.

- Integrate Systems: Ensure your order processing system communicates seamlessly with inventory and CRM systems. This integration is crucial for real-time stock updates and personalized customer interactions. For instance, when an order is placed, your inventory system should automatically update, preventing overselling.

- Optimize Inventory Management: Maintain accurate stock levels to avoid fulfillment delays. Implement a system that alerts you when stock reaches a predetermined threshold. This proactive approach ensures you can reorder popular items before they run out. For instance, the assortment intelligence solutions from FCC have been helping retailers predict demand and effortlessly optimize their inventory levels.

- Focus on Customer Communication: Keep customers informed at every stage of their order’s journey. Set up automated notifications for order confirmation, shipping, and delivery. Consider implementing a self-service portal where customers can track their orders in real time.

- Train Your Team: Invest in comprehensive training for your staff on all order processing tools and procedures. Regular workshops and hands-on sessions can significantly improve efficiency and reduce errors. Create detailed process documents for quick reference during daily operations.

- Monitor and Analyze: Utilize analytics tools to identify bottlenecks in your order processing workflow. Track key metrics like order processing time, error rates, and customer satisfaction scores. Use this data to refine and improve your business processes continuously.

What are the Key Order Processing Performance Metrics?

Here are the key performance metrics that you must monitor to identify inefficiencies and enhance performance of your order processing system.

-

Turnaround Time: Measure the elapsed time from order placement to final delivery using the formula:

Turnaround Time = Order Delivery Time – Order Placement Time

Shorter turnaround times indicate a streamlined order processing system, which leads to increased customer satisfaction.

-

Accuracy Rate: Calculate accuracy rate as:

Accuracy Rate = (Number of Error-Free Orders / Total Orders Processed) × 100

This metric reflects your system’s precision, ensuring reliable order processing while reducing costly errors.

-

Fulfillment Rate: Assess fulfillment rate with the following formula:

Fulfillment Rate = (Orders Delivered On Time / Total Orders Processed) × 100.

High fulfillment rates signify effective logistics and robust order processing.

-

Customer Satisfaction Score: Gauge customer satisfaction through surveys using the following formula:

CSAT = (Number of Satisfied Customers / Total Number of Survey Responses) x 100

High scores reveal positive order processing experiences and help you identify areas for improvement.

The Role of Technology in Modern Order Processing

Advanced technological solutions like Warehouse Management Systems (WMS) and Order Management Software are helping businesses streamline their order processing, reduce errors, and improve efficiency.

Artificial Intelligence (AI) is taking these improvements even further. By leveraging AI, businesses can optimize inventory levels, predict demand patterns, and enhance decision-making processes. AI also plays a crucial role in order fulfillment, prioritizing orders based on various parameters such as delivery deadlines and customer importance.

The integration of these technologies offers improved scalability, allowing businesses to handle higher order volumes without compromising accuracy or efficiency. This is particularly crucial during peak seasons or periods of rapid growth.

Flipkart Commerce Cloud (FCC) offers a comprehensive suite of retail solutions that helps companies leverage these latest technological advancements to streamline their processes. Our Order Management System automates workflows at every stage of fulfilment and our Warehouse Management System provides powerful inventory control. These solutions enable real-time inventory tracking, allowing you to maintain optimal stock levels and prevent stockouts.

FCC’s AI-driven predictive analytics help you anticipate changes in consumer demand and identify potential bottlenecks in your supply chain. This proactive approach allows you to adapt quickly to market shifts and maintain customer satisfaction. Our real-time tracking capabilities keep both businesses and customers informed throughout the order lifecycle. This enhanced transparency builds trust and improves the overall customer experience.

Conclusion

Order processing plays a pivotal role in modern commerce and logistics, directly impacting your operational efficiency and customer satisfaction. By leveraging advanced technologies and adopting best practices, you can streamline your order processing workflow, reduce errors, and enhance the overall customer experience. Embracing these innovations will help improve your current operations and position your business for success in the competitive retail ecosystem.

FAQ

Order processing involves capturing, verifying, and managing customer orders from placement to dispatch. Order fulfillment extends this cycle to include picking, packing, shipping, and final delivery. While order processing focuses on data accuracy and system integration, order fulfillment ensures that customers receive their products promptly and in excellent condition.

Retailers manage high-volume order processing by implementing scalable automation and integrated solutions. You rely on real-time analytics and inventory tracking to adjust workflows and prevent bottlenecks. Robust platforms streamline operations, ensuring that your team can efficiently handle peak demand without compromising service quality.

Automation enhances order processing by eliminating manual tasks and reducing human error. Software is used to capture orders accurately, update inventory, and notify customers in real time. Integrated systems like Flipkart Commerce Cloud enable seamless data flow, ensuring faster processing and improved reliability.