Table of Contents

- What is Picking and Packing?

- Types of Picking Methods

- Types of Packing Methods

- What is the Importance of Efficient Picking and Packing?

- What are the Key Challenges in Picking and Packing?

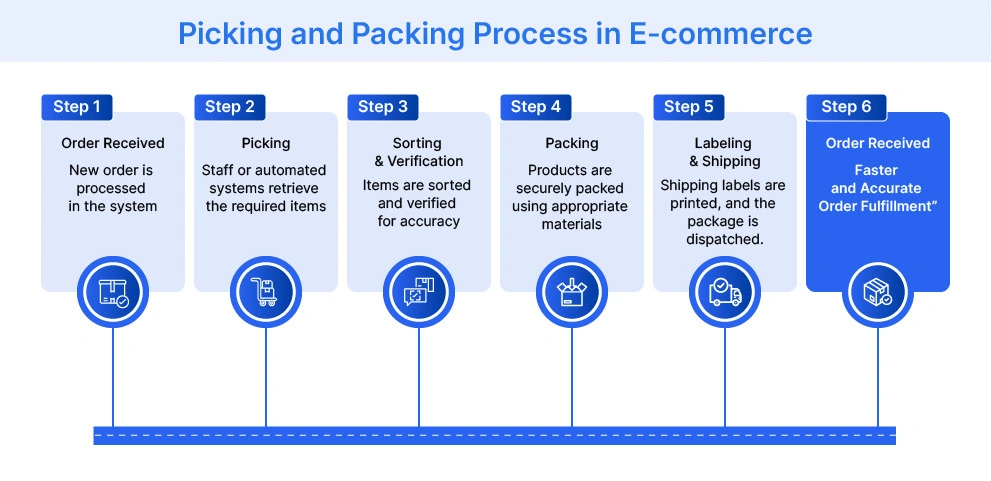

What is Picking and Packing in Warehouse?

Picking and packing are two-step processes essential for smooth warehouse operations and order fulfillment. These interconnected activities ensure that customers receive the right products in optimal condition.

Understanding the Picking and Packing Meaning

Picking is the systematic retrieval of items from warehouse shelves or storage locations. It involves navigating the warehouse efficiently to collect specific products listed in customer orders. Order picking process requires precision and speed to maintain inventory accuracy and meet fulfillment deadlines.

Packing, on the other hand, is the process of securely preparing picked items for shipment. The entire pack process includes selecting appropriate packaging materials, arranging products to prevent damage during transit, and including necessary documentation such as a packing slip. Effective packing balances protection with cost-efficiency, ensuring items arrive intact without excessive material use.

Together, picking and packing form a critical link between inventory management and customer satisfaction. As a result, an increasing number of retailers are leveraging Warehouse Management Systems (WMS) and automation tools to streamline picking and packing for improved efficiency.

Types of Picking Methods

Warehouse operations employ various picking techniques to enhance efficiency and accuracy. Understanding these methods can help optimize the picking process for maximum productivity.

Piece Picking

Piece picking, also known as discrete picking, involves collecting items for a single order at a time. In this method, warehouse staff moves through the warehouse for the selection of products listed on a single order before proceeding to the next.

How it’s done

Warehouse workers receive a picking list and navigate the warehouse, collecting each item individually. They complete one order before moving on to the next, ensuring focused attention on each customer’s requirements.

Benefits

- Ideal for retail businesses with a high volume of small orders

- Reduces the risk of mixing up items between different orders

- Allows for easy order customization and special handling

Batch Picking

This warehouse-picking technique involves simultaneously collecting items for multiple orders. This method groups similar orders together, allowing pickers to retrieve items for several orders in a single trip through the warehouse.

How it’s done

Pickers receive a consolidated list of items from multiple orders. They collect all required items in one go and later sort them into individual orders at a packing station.

Benefits

- Increases picking efficiency by reducing travel time in the warehouse

- Suitable for businesses with many similar orders or frequently ordered items

- Helps balance workload across pickers, especially during peak periods

Table Title: Types of Picking Methods

|

Picking Method |

How It’s Done |

Key Benefits |

|

Piece Picking |

Pickers fulfill one order at a time, selecting items individually. |

Ideal for small orders, reduces item mix-ups, and allows customization. |

|

Batch Picking |

Pickers collect items for multiple orders in one trip. |

Saves time, improves efficiency, and balances workload. |

|

Zone Picking |

The warehouse is divided into zones, and pickers focus on assigned areas. |

Reduces congestion, increases specialization, and is ideal for large warehouses. |

|

Wave Picking |

Orders are grouped into waves based on priority or shipping deadlines. |

Enhances scheduling, prioritizes urgent orders, and adapts to demand fluctuations. |

Zone Picking

Zone picking divides the warehouse into distinct areas or zones, with dedicated pickers assigned to each zone. Orders move from zone to zone, with each picker adding the required items from their assigned area.

How it’s done

The number of orders is passed through different zones sequentially. Pickers in each zone add the required items from their area before passing the order to the next zone.

Benefits

- Reduces congestion in the warehouse by keeping pickers in specific areas

- Allows for specialization, as pickers become experts in their assigned zones

- Scalable for large warehouses with diverse product ranges

Wave Picking

Wave picking combines elements of batch and zone picking. It involves scheduling picking tasks in waves or time slots, often aligning with outbound shipping schedules or other operational constraints.

How it’s done

Orders are grouped into waves based on factors like shipping deadlines or destination. Pickers work on these waves, often using a combination of batch and zone-picking methods.

Benefits

- Allows for precise scheduling and workload management

- Helps prioritize orders based on shipping deadlines or other criteria

- Provides flexibility to adapt to changing order volumes throughout the day

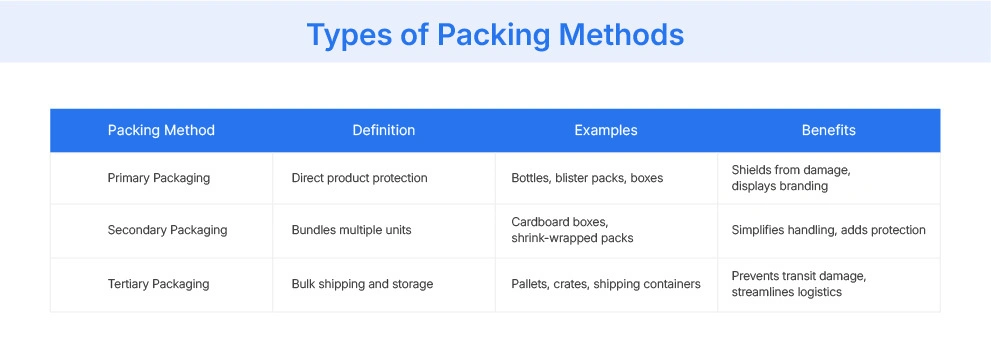

Types of Packing Methods

Let's have a closer look at the different pack methods available to ensure product safety during transit:

Primary Packaging

Primary packaging is the first layer of protection that directly contacts the product. It is often the packaging that remains with the item until the consumer uses it. For instance, enclosing individual items in their immediate containers, such as bottles for liquids, blister packs for tablets, or boxes for electronics.

Benefits

- Protects products from contamination and environmental factors

- Provides a surface for essential product information and branding

Secondary Packaging

This method groups multiple units of primary-packaged products together. It provides an additional layer of protection and serves as the packaging visible to consumers in retail settings. For example, bundling multiple primary packages into a larger container, such as a cardboard box.

Benefits

- Simplifies handling and storage of multiple units

- Offers additional protection during transportation and warehouse handling

Tertiary Packaging

Also known as transit packaging, this method is used for bulk handling, warehouse storage, and shipping. It is designed to protect large quantities of products during transportation and distribution. For instance, multiple secondary packages are grouped onto pallets, in large boxes, or in shipping containers.

Benefits

- Provides robust protection against damage during transportation and handling

- Allows for easy tracking and management of inventory in bulk

What is the Importance of Efficient Picking and Packing?

Efficient picking and packing are crucial for accurate order fulfillment and a smooth customer experience. A streamlined system optimizes warehouse operations, accelerates deliveries, and ultimately boosts customer satisfaction. Optimizing these workflows minimizes wasted motion and prevents costly shipping errors.

A Warehouse Management System (WMS) is key to achieving this goal. It provides real-time inventory tracking, minimizes unnecessary handling, and improves overall efficiency. A WMS also automates order routing, selects the most effective picking strategies, and ensures precise packing.

Modern fulfillment centers leverage WMS integration to achieve these operational efficiencies at scale. Further enhancements, such as automation and strategic inventory placement, minimize retrieval and packing time. They create an agile and scalable fulfillment process capable of meeting evolving customer demands. Implementing best practices in order fulfillment strategies helps ensure a robust inventory management system.

What are the Key Challenges in the Picking and Packing Process?

Here are the key challenges in picking and packing that can directly impact warehouse operations:

- Inventory Management: Accurate inventory tracking is essential for smooth picking and packing operations. Inaccurate records can lead to stockouts, overstocking, and inefficient use of warehouse space. Real-time inventory visibility is crucial to prevent these issues and ensure that pickers can quickly locate and retrieve the correct items.

- Order Accuracy: Errors in order processes can result in customer dissatisfaction, increased returns, and additional shipping costs. Implementing systems that reduce human error and provide clear picking instructions is vital for improving accuracy.

- Labor Costs: Picking and packing are labor-intensive processes. Efficiently managing the workforce while maintaining productivity can be challenging, especially during peak seasons when temporary staff may be required.

- Packaging Waste: Balancing product protection with minimizing packaging waste is a growing concern. Finding eco-friendly packaging solutions that don’t compromise product safety or increase costs is a significant challenge for many businesses.

How OMS and WMS Can Help?

Order Management Systems (OMS) and Warehouse Management Systems (WMS) provide up-to-date inventory information, reducing stockouts and improving picking efficiency.

WMS can generate optimized picking paths, reducing travel time and increasing productivity, whereas OMS automates order flow from receipt to fulfillment, minimizing manual errors and speeding up the process.

Integrating WMS and OMS is vital to streamline operations and minimize unnecessary movement. As e-commerce grows, adopting automation and data-driven strategies in picking and packing ensures scalability while meeting evolving customer expectations.

Flipkart Commerce Cloud (FCC) offers robust warehouse management software that effectively addresses these challenges. Our WMS seamlessly integrates with Order Management Systems to provide:

- Real-time inventory tracking across locations

- Optimized picking paths for increased productivity

- Automated order flow from receipt to fulfillment

- Data-driven strategies for scalable operations

By leveraging FCC's WMS, businesses can streamline their warehouse operations, reduce errors, and control costs while meeting evolving customer expectations efficiently.

Book a demo today and discover how FCC can streamline your warehouse management.

FAQ

Pick packing is a specific warehouse labor category where a single individual or a coordinated team is responsible for the entire sequence of identifying, grabbing, and boxing goods for delivery. This process relies heavily on an organized inventory system where every item has a designated location to minimize the time spent searching. To optimize this exact function, FCC provides digital solutions that track inventory levels in real time, ensuring that pick packers always have the most accurate information to fulfill orders without delays or stockouts.

Picking and packing is often perceived as an easy process, but it requires a high level of organization, speed, and accuracy to be performed effectively. The difficulty often increases as the volume of orders grows, requiring workers to navigate complex warehouse layouts and handle various product types with care. Modern logistics teams frequently utilize advanced warehouse management systems, such as those optimized by FCC, to simplify these tasks through digital route planning and automated scanning, which reduces human error and physical strain on the staff.

Picking and packing is often called order fulfillment or warehouse fulfillment within the broader context of logistics and distribution. In some specialized environments, it may also be described as the broken case or piece pick process, highlighting that individual items are being handled rather than full pallets or crates. Professionals using the FCC infrastructure frequently categorize these activities under outbound logistics, emphasizing their role in the final stage of moving goods from a storage facility directly to the end consumer.

Yes, sustainability is becoming increasingly important in picking and packing operations. Many businesses are adopting eco-friendly packaging materials and optimizing package sizes to reduce waste. Some are implementing reusable containers for internal processes. There is also a growing trend towards using data analytics to optimize routes and reduce energy consumption in warehouses.

Several tools can enhance your picking and packing operations:

-

Barcode scanners and RFID technology improve accuracy and speed.

-

Mobile devices with real-time inventory updates streamline the picking process.

-

Automated packaging machines can optimize packing efficiency.

-

WMS and OMS provide comprehensive solutions for managing the entire process.

Picking involves selecting the correct items from your inventory based on customer orders. Packing, on the other hand, is the process of securely preparing these picked items for shipment. While picking focuses on accuracy and speed in item retrieval, packing emphasizes proper protection and presentation of products for transit.