Table of Contents

- What is Just-in-Time Inventory?

- History of Just-in-Time Inventory

- How Does JIT Inventory Work?

- Examples of Just-in-Time Inventory

- What is the Difference Between JIT and Traditional Inventory Management?

- What are the Benefits of Just-in-Time Inventory?

- What are the Disadvantages of Just-in-Time Inventory?

- Who Can Use Just-in-Time Inventory Methodology?

- How to Implement a JIT Inventory System?

- Why is Kanban Important in the JIT Inventory?

- Conclusion

What is Just-in-Time Inventory?

Just-in-Time inventory is an operational strategy that involves receiving and managing stock to coincide precisely with when it is needed in the production cycle or to meet customer demand. This approach eliminates the need for large stockpiles of goods.

Instead of holding extensive safety stock, your business orders materials from suppliers on an as-needed basis, which requires highly coordinated scheduling and delivery processes.

The primary goal of JIT inventory management strategy is to minimize the costs associated with holding inventory while simultaneously improving your business's return on investment.

- It significantly reduces the costs tied to storing and managing excess inventory.

- The system increases efficiency by streamlining the production workflow from start to finish.

- It minimizes material waste by ordering only what is immediately required for production.

- This approach strengthens supplier relationships through frequent and reliable communication and coordination.

- It improves cash flow by freeing up capital previously tied up in unsold stock.

History of Just-in-Time Inventory

The concept of Just-in-Time inventory originated in Japan during the post-World War II economic recovery. Toyota Motor Corporation is widely credited with developing and refining the Toyota Production System (TPS) as a core component during the 1970s.

Toyota’s goal was to eliminate all forms of waste in the manufacturing process, from excess inventory to unnecessary movement of materials. Taiichi Ohno, a Toyota industrial engineer, pioneered this system to create a lean, efficient production line capable of responding quickly to market changes.

This effective inventory management approach was revolutionary, challenging the prevailing Western "just-in-case" model of stockpiling inventory. Its success at Toyota demonstrated its power, and the methodology was subsequently adopted by manufacturers and retailers across various industries worldwide, transforming modern supply chain management.

How Does JIT Inventory Work?

The Just-in-Time inventory system operates on a "pull" basis, meaning production is dictated by actual customer demand rather than forecasting. When a customer places an order, it creates a signal that travels backward through the supply chain, initiating production and material procurement.

This process starts at the final assembly stage and moves upstream. Each workstation or production cell requests the necessary parts from the previous station only when it has the capacity to process them. This domino effect ensures that materials are not pushed into the system before they are needed.

Consequently, components and raw materials arrive from suppliers at the exact moment they are required for manufacturing. This eliminates the need for extensive on-site storage capacity, as goods are moved directly from receiving docks to the production floor, promoting a continuous and smooth workflow in supply chain operations.

A successful JIT system requires exceptional coordination and visibility across your entire supply chain. Strong partnerships with reliable suppliers are critical, as their ability to deliver quality materials on schedule directly impacts your production capabilities and ability to satisfy customer orders promptly.

Examples of Just-in-Time Inventory

Here are a few real-world examples that illustrate how different industries effectively apply the Just-in-Time inventory model.

- Toyota: The automaker orders parts only when a new vehicle order is received. Suppliers deliver components directly to the assembly line in small, frequent batches, which minimizes the need for large warehouses and keeps inventory costs low while maintaining production flow.

- Dell: Dell revolutionized the personal computer market by building computers to order. Customers customize their PCs online, and Dell's JIT system pulls the necessary components from suppliers to assemble the specific configuration, drastically reducing its stock of finished goods.

- McDonald's: To ensure freshness, McDonald's kitchens operate on a JIT basis. Food items like buns and patties are cooked only after a customer places an order, which helps with waste reduction and guarantees that customers receive a freshly prepared meal every time.

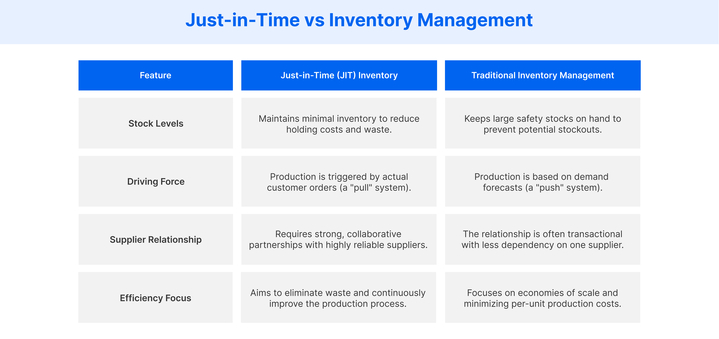

What is the Difference Between JIT and Traditional Inventory Management?

The key difference between Just-in-Time inventory and traditional inventory management lies in their fundamental approach. JIT is a "pull" system driven by actual demand, while traditional models use a "push" system based on sales forecasts to stock up inventory in anticipation of future demand.

What are the Benefits of Just-in-Time Inventory?

The benefits of JIT inventory management system are centered on efficiency, cost reduction, and improved resource management.

- Reduced Warehousing Costs: You significantly lower expenses tied to storage space by holding minimal stock. This reduces costs for rent, security, insurance, and labor required to manage a large warehouse.

- Improved Cash Flow: By purchasing inventory only as required for production or sales, you free up valuable capital that would otherwise be tied up in unsold stock sitting on shelves.

- Minimized Waste and Obsolescence: Ordering in smaller, frequent batches drastically reduces the risk of inventory becoming outdated, damaged, or expiring, which is especially crucial for perishable or trend-sensitive goods.

- Increased Production Efficiency: A simplified workflow with less inventory on the floor means less clutter, faster material handling, and fewer production delays, leading to a more efficient and productive operation.

What are the Disadvantages of Just-in-Time Inventory?

Here are the disadvantages of the JIT inventory management system that need timely resolution:

- Vulnerability to Supply Chain Disruptions: Unexpected events like transportation delays, natural disasters, or supplier issues can halt your entire production line, as you have no safety stock to fall back on.

- Risk of Stockouts: A sudden, unforeseen surge in customer demand can quickly deplete your minimal inventory, leading to stockouts, missed sales opportunities, and potential damage to customer satisfaction.

- Heavy Reliance on Supplier Performance: Your entire operation depends on suppliers delivering the correct, high-quality materials exactly on time. Any failure on their part can create immediate and significant production bottlenecks.

- Higher Ordering and Transport Costs: You may lose out on bulk purchasing discounts and face higher transportation costs due to the need for frequent, smaller deliveries to maintain your minimal inventory levels.

Who Can Use Just-in-Time Inventory Methodology?

Just-in-Time inventory management is most effective for businesses that operate in stable, predictable environments. Companies with consistent production schedules and reliable demand patterns are ideal candidates, as these factors reduce the risk of unexpected supply chain delays.

Industries like automotive manufacturing, electronics assembly, and fast-food restaurants often see great success with the JIT strategy. These sectors typically benefit from high-volume production and have established processes that allow for precise coordination with suppliers and subcontractors for timely deliveries.

Businesses with strong, long-term relationships with their suppliers are better positioned to implement JIT. Trust and open communication are essential to ensure materials are delivered on time and meet quality standards, which is a cornerstone of the entire system.

Retailers with advanced demand forecasting capabilities and dependable logistics partners can also leverage JIT. By accurately predicting sales, they can schedule inventory arrivals to match customer purchasing cycles, minimizing overstocking and improving turnover rates for their product lines.

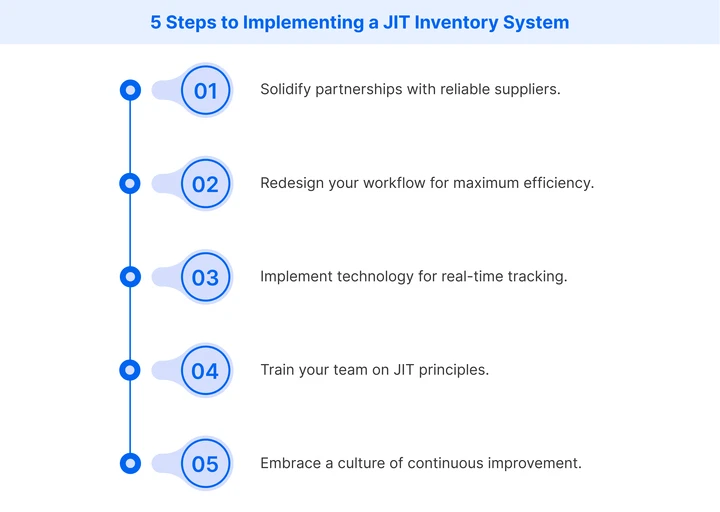

How to Implement a JIT Inventory System?

Successfully implementing a Just-in-Time inventory system requires careful planning and a commitment to operational excellence. It involves the following steps:

Foster Strong Supplier Partnerships

Build collaborative, long-term relationships with your suppliers. Reliable partners who can consistently meet delivery schedules and quality standards are the foundation of a successful JIT system. Establish clear communication channels and shared performance metrics to ensure alignment and mutual trust.

Design an Efficient Workflow

Analyze and map your entire production process to identify and eliminate waste, such as unnecessary movement or delays. Organize workstations in a logical sequence to create a smooth, continuous flow of materials from receiving to final assembly, minimizing handling and transit time.

Leverage Advanced Technology

Utilize technology to automate and manage inventory signals and production schedules. An integrated system is crucial for real-time visibility and control. Flipkart Commerce Cloud Inventory Management System, for instance, offers robust tools for real-time inventory tracking, order management, and multi-channel fulfillment.

It helps you accurately monitor stock levels across all locations and automate reordering based on preset thresholds, providing the technological backbone for an effective JIT inventory strategy.

Train and Empower Your Team

Ensure your entire team understands the principles and operational requirements of the JIT methodology. Empower employees to identify production issues and suggest improvements. A culture of continuous improvement, or "kaizen," is essential for refining processes and adapting to changing demands over time.

Why is Kanban Important in the JIT Inventory?

Kanban is a visual management tool that serves as the nervous system of a Just-in-Time inventory system. Its name translates to "visual signal" or "card" in Japanese, and it functions precisely that way, providing cues to trigger action within the production process.

In a JIT environment, Kanban cards or digital signals are used to communicate that a specific part or material has been consumed and needs to be replenished. When a worker uses the last component from a bin, the attached Kanban card is sent back to the previous station as a signal to produce more.

This simple yet powerful mechanism ensures that production is directly linked to real-time consumption. It prevents overproduction by authorizing the creation of new parts only when they are needed, making the "pull" system a tangible reality on the factory or warehouse floor.

Conclusion

Just-in-Time Inventory offers retailers and manufacturers a lean approach to managing stock, reducing waste, and improving efficiency. While its success depends on strong supplier networks and accurate demand forecasting, businesses adopting JIT gain flexibility, lower costs, and better alignment with customer needs. With the right systems, JIT can transform inventory into a competitive advantage.

FAQ

JIT reduces warehousing costs by minimizing the amount of inventory you hold at any given time. With less stock on hand, you require smaller storage facilities, which lowers expenses related to rent, utilities, insurance, and labor for inventory control.

Yes, small retailers can implement Just-in-Time inventory, especially if they have reliable local suppliers and predictable sales for certain products. Using modern POS and inventory management software helps them track sales in real-time and automate orders to align with demand.

JIT is a "pull" system focused on ordering inventory only when needed to minimize holding costs. In contrast, EOQ is a formula used in "push" systems to calculate the optimal order size that minimizes total inventory costs, including both holding and ordering costs.

The core principles of JIT include eliminating all forms of waste, producing goods only as needed based on customer demand, continuous process improvement (kaizen), and fostering strong, collaborative relationships with suppliers to ensure a smooth and efficient supply chain.