Table of Contents

- What is Real-Time Inventory

- Why is Real-Time Inventory Important for Retailers?

- How Does Real-Time Inventory Management Work

- real-time Inventory vs. Periodic Inventory: How they Differ

- What are the Key Benefits of Real-Time Inventory

- What are the Challenges in Implementing Real-Time Inventory

- How Can Businesses Implement Real-Time Inventory

- How Does Real-Time Inventory Support Omnichannel Retail Strategies

- Conclusion

What is Real-Time Inventory?

Real-time inventory systems offer businesses instant, precise visibility into their entire stock landscape. Retailers immediately know exact product quantities available across all locations and sales channels.

This dynamic system continuously tracks inventory movements and updates counts automatically as transactions occur. This live, accurate data is essential for informed decision-making and effective operational control. Compared to traditional inventory management methods, real-time inventory handling methods eliminate the delay in understanding current stock availability.

This continuous visibility is powered by advanced processes and technologies like artificial intelligence and machine learning; here is precisely how a real-time inventory system operates:

- Systems instantly capture inventory data at various points using tools like barcode scanners or RFID readers.

- The software immediately updates stock levels whenever items are received, sold, returned, or moved.

- Businesses integrate all sales channels, including online stores and physical locations, for centralized data access.

- Automated processes track stock movement across multiple warehouses and fulfillment centers simultaneously.

- The system utilizes software that consolidates data and provides immediate alerts on stock status changes.

Why is Real-Time Inventory Important for Retailers?

Real-time inventory is crucial for retailers seeking operational excellence and enhanced customer satisfaction in the current market. Here is why this system is important for retailers:

- It provides retailers with accurate, immediate data on stock levels across all sales channels and locations continuously.

- Retailers make faster, better decisions regarding purchasing, transfers, and promotions based on live inventory data availability.

- Real-time inventory significantly improves operational efficiency by reducing time spent on manual checks and correcting stock errors.

- It helps prevent costly stockouts, ensuring products are available precisely when customers are ready to purchase them.

- The system minimizes overstocking, freeing up valuable capital previously tied up in excess, slow-moving inventory items.

How Does Real-Time Inventory Management Work?

An effective inventory management solution relies on integrating various technologies and automated processes to ensure continuous, instantaneous stock visibility across operations:

- Data Capture Technologies: Barcode scanners, RFID tags, and IoT sensors track product movements by instantly registering when items enter or leave your inventory through receiving, sales, returns, or transfers between locations.

- Centralized Management Software: Cloud-based inventory platforms serve as the central nervous system that processes incoming data from all channels, updates inventory records, and distributes this information to all connected systems simultaneously.

- System Integration Architecture: APIs and middleware connect your inventory management processes with other business applications like POS terminals, e-commerce platforms, Warehouse Management Systems (WMS), and Order Management System (OMS) to maintain data consistency.

- Automated Alert Mechanisms: Pre-configured thresholds trigger notifications when inventory levels approach reorder points, demand patterns shift unexpectedly, or discrepancies arise between physical counts and system records.

- Real-Time Analytics Engine: Advanced reporting tools continuously process inventory data to generate actionable insights on sales velocity, stock turnover rates, key performance indicators, and inventory accuracy across locations.

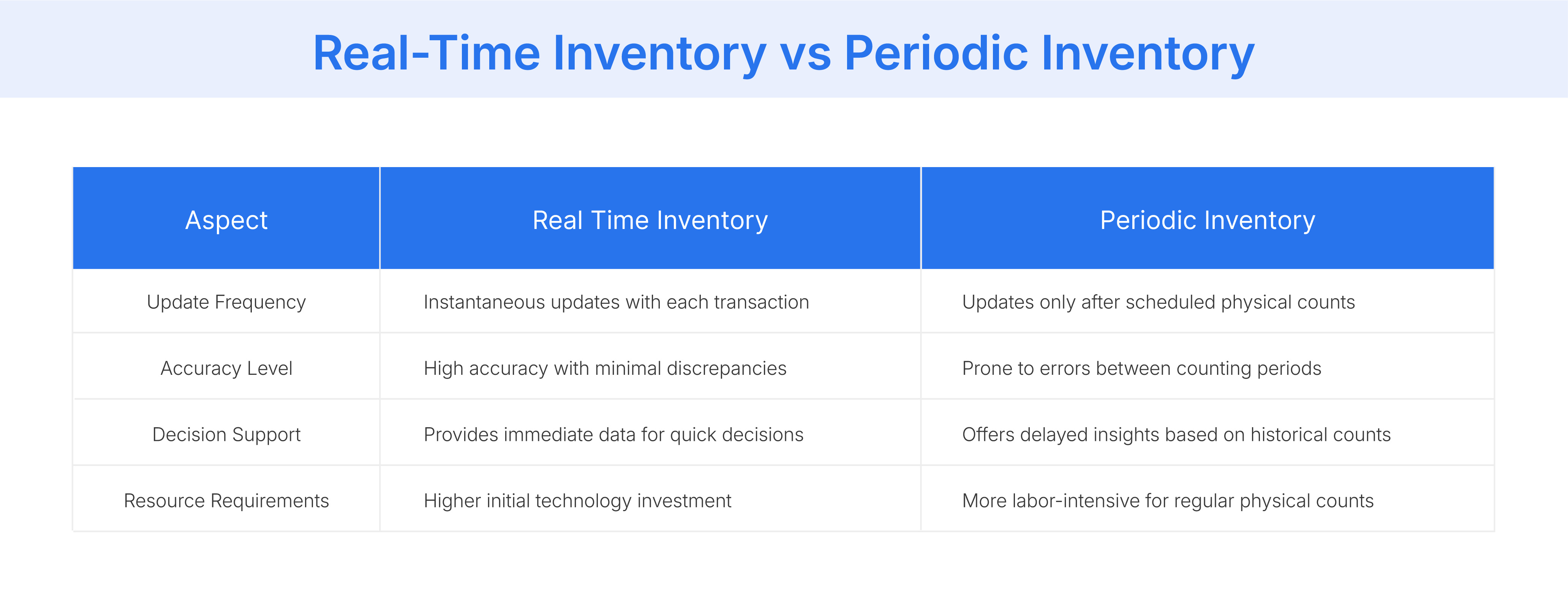

real-time Inventory vs. Periodic Inventory: How they Differ?

Real-time inventory and periodic inventory represent fundamentally different approaches to tracking stock levels. While real-time inventory continuously updates with each transaction, periodic inventory control relies on scheduled physical counts to reconcile system records. This fundamental difference impacts accuracy, business agility, and operational efficiency across retail environments.

What are the Key Benefits of Real-Time Inventory?

Implementing real-time inventory systems provides significant advantages for retailers, enhancing operational efficiency and elevating customer satisfaction substantially.

- It improves inventory data accuracy significantly by automating tracking processes and reducing manual errors in stock records.

- Retailers can reduce costly stockouts and minimize overstocking issues by gaining precise knowledge of current stock levels.

- Customer satisfaction increases because retailers can confidently offer products available for immediate purchase or alternative fulfillment.

- Order fulfillment processes become significantly optimized, allowing faster picking, packing, and shipping based on accurate location data.

- It enables better forecasting and planning by providing reliable historical and current data on product movement trends.

What are the Challenges in Implementing Real-Time Inventory?

Adopting real-time inventory systems for supply chain needs can present certain challenges for retailers, requiring careful planning, resource allocation, and adjustments to established practices.

- The initial investment in required hardware like scanners, software licenses, and necessary infrastructure can represent a significant upfront cost.

- Integrating the new real-time inventory system with existing platforms, such as POS, ERP, or e-commerce sites, can be technically complex.

- Requires comprehensive training for staff members across all relevant departments to utilize the new technology and follow updated processes effectively.

- Businesses need to adjust existing workflows and establish standardized procedures for consistent data capture across all operational activities.

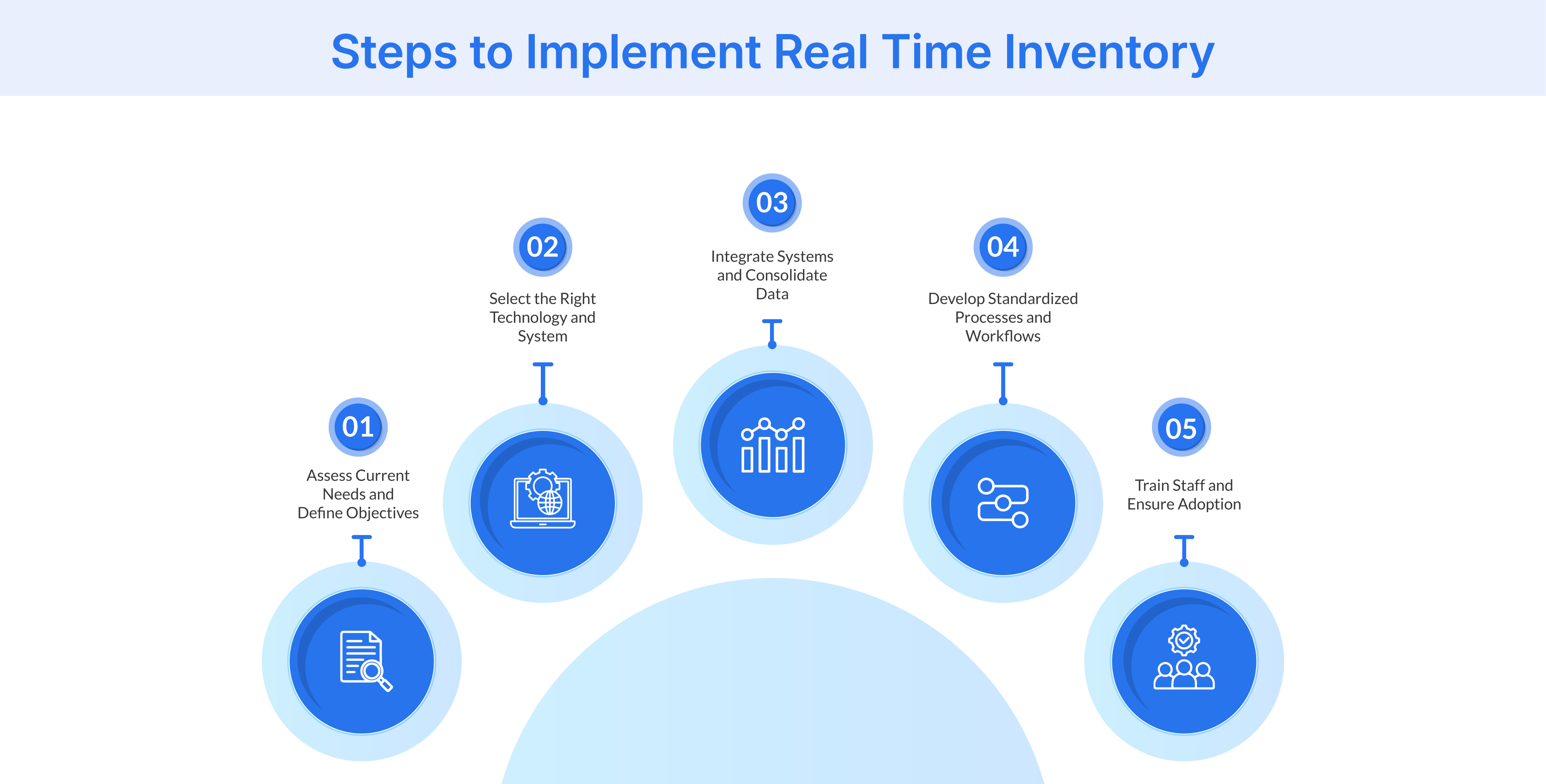

How Can Businesses Implement Real-Time Inventory?

Implementing a real-time inventory system for optimal supply chain management involves the following strategic steps:

Assess Current Needs and Define Objectives

Businesses should start by thoroughly evaluating their existing inventory processes to identify inefficiencies and pain points. Clearly define specific objectives that the business aims to achieve with real-time Inventory, setting measurable goals for the implementation project's success and impact.

Select the Right Technology and System

Select suitable hardware, such as barcode scanners or RFID readers, and choose robust software, such as a dedicated inventory management system or a Warehouse Management System (WMS). Ensure the chosen technology aligns perfectly with identified business requirements and supports seamless real-time inventory tracking capabilities.

Integrate Systems and Consolidate Data

Establish seamless connections between the new real-time inventory system and other key business platforms. Integrate systems like POS, e-commerce platforms, and ERP to consolidate data flow and ensure real-time updates occur across all sales and operational channels.

Develop Standardized Processes and Workflows

Create clear, standardized procedures for all inventory-related activities to ensure consistent data capture. Define consistent workflows for receiving new stock, picking orders, packing shipments, handling returns, and conducting transfers accurately within the system.

Train Staff and Ensure Adoption

Provide comprehensive training programs for all employees involved in inventory management operations at every level. Equip staff with the necessary skills to effectively use the new real-time inventory technology and diligently follow the standardized processes for optimal system utilization and data accuracy.

How Does Real-Time Inventory Support Omnichannel Retail Strategies?

Real-time inventory serves as the foundation for successful omnichannel retail by providing a single source of truth across all sales channels. Retailers implement these systems to enable Buy Online Pickup In Store (BOPIS), curbside pickup, and ship-from-store services that rely on full visibility of accurate inventory levels to prevent customer disappointment.

The unified inventory data powers distributed order management capabilities that intelligently route orders to optimal fulfillment locations. Modern order management systems leverage this real-time data to determine whether to fulfill orders from distribution centers, retail stores, or through dropshipping arrangements, maximizing efficiency and speed.

Store associates benefit from comprehensive inventory visibility through clienteling applications that display product availability across the entire retail network. This transparency enables associates to place special orders or arrange transfers when items aren’t available locally, ensuring consistent customer experiences across all shopping channels.

Real-time inventory enables retailers to implement endless aisle capabilities that extend their physical selection through digital touchpoints. These systems also support advanced analytics that help optimize inventory distribution, ensuring products are available in the right locations to meet localized demand patterns and reduce lost sales opportunities.

Conclusion

Real-time inventory plays a critical, indispensable role in modern retail and e-commerce environments. Its capacity to provide immediate, accurate stock visibility across all channels empowers businesses to achieve significant operational efficiency and enhance customer satisfaction effectively.

By enabling informed decisions, reducing stock issues, and supporting flexible fulfillment strategies such as Buy Online, Pick Up In-Store (BOPIS) and ship-from-store, real-time inventory is essential for navigating the complexities of omnichannel retail successfully and maintaining a competitive edge in the market.

FAQ

Essential technologies for effective real-time inventory tracking include barcode scanners, RFID readers, and IoT devices for automated data capture at various points. Robust inventory management software integrated with WMS, OMS, and POS systems forms the critical backbone for data processing and visibility.

Yes, a core function of real-time inventory systems is managing stock across multiple warehouses and fulfillment locations simultaneously. The centralized database aggregates data from all sites, providing businesses with a unified, immediate view of total inventory availability across their network.

Real-time inventory data significantly improves demand forecasting accuracy. By providing precise, timely information on sales patterns, current stock levels, and historical movements, businesses gain deeper insights into actual product demand trends. This enables more accurate predictions for future inventory needs and strategic planning.

While real-time inventory systems maintain high accuracy, periodic reconciliation through cycle counts or less frequent full physical inventories is still recommended. Retailers perform this to verify system accuracy against physical stock and investigate any significant discrepancies found, ensuring data integrity.