Table of Contents

- Understanding Demand Forecasting

- What Is Demand Forecasting?

- Benefits of Demand Forecasting?

- Qualitative vs. Quantitative Demand Forecasting

- How to Forecast Demand Like a Pro (A 5-Step Process)

- Forecasting With Flipkart Commerce Cloud

Understanding Demand Forecasting

You have likely experienced the frustration of visiting a store for a specific item only to find empty shelves. This scenario represents the chaotic nature of supply chain logistics when customer demand outpaces availability. Retailers often struggle to balance having enough stock without overcommitting resources to products that might not sell.

Effective business planning requires moving away from guesswork and embracing data-driven strategies. You must understand what your customer base will crave next month or next year to maintain operational efficiency.

Here are the key aspects of demand forecasting:

- You utilize historical data to identify market trends that inform your future sales predictions and inventory management decisions.

- It transforms raw data points into valuable insights that help you align your supply chain management with reality.

- You leverage forecasting methods to optimize resource allocation and ensure customer satisfaction remains high across all channels.

- This process allows you to prepare for seasonal fluctuations and market changes by analyzing demand patterns effectively.

What Is Demand Forecasting?

Demand forecasting is the process of using historical sales data and market research to estimate future consumer appetite. It combines quantitative forecasting with qualitative methods to predict how much product you need to order. This approach ensures you meet customer needs without tying up capital in excess stock.

Achieving this level of precision requires more than just intuition. The difference between a hunch and a forecast lies in the reliance on data analysis versus gut feeling. While a hunch can guess the outcome, accurate demand forecasting uses machine learning and economic trends to build confidence. It provides a solid foundation for your financial planning and marketing strategies.

What are the Benefits of Demand Forecasting?

Accurate predictions prevent costly mistakes and drive growth. Here is how effective demand forecasting impacts your bottom line and inventory levels:

- Overstocking: Holding excess inventory results in money collecting dust on warehouse shelves rather than generating cash flow. Optimal inventory levels prevent you from tying up capital in products that have low market demand. You avoid the need for markdowns that erode your profit margins and devalue your brand image.

- Understocking: The 'Out of Stock' button drives potential customers directly to your competitors and hurts your long-term business strategies. Missed sales opportunities due to poor demand planning damage your reputation and frustrate buyers. Ensuring availability is the best way to maintain customer satisfaction and secure repeat business.

- Happier Customers: Shoppers expect to get what they want exactly when they want it without delays or excuses. Accurate forecasts ensure you have the right products available to fulfill orders immediately upon request. This reliability builds trust and strengthens the relationship between your brand and its loyal customer base.

- Leaner Budgets: You stop buying inventory that will not sell and focus your budget on high-performing items. Resource allocation becomes more efficient when you base purchasing decisions on accurate predictions rather than speculation.

- Better Pricing: Knowing future demand helps you plan promotions effectively and avoid panic discounting to clear stagnant stock. You can adjust pricing strategies based on anticipated market conditions to maximize revenue during peak periods.

Qualitative vs. Quantitative Demand Forecasting

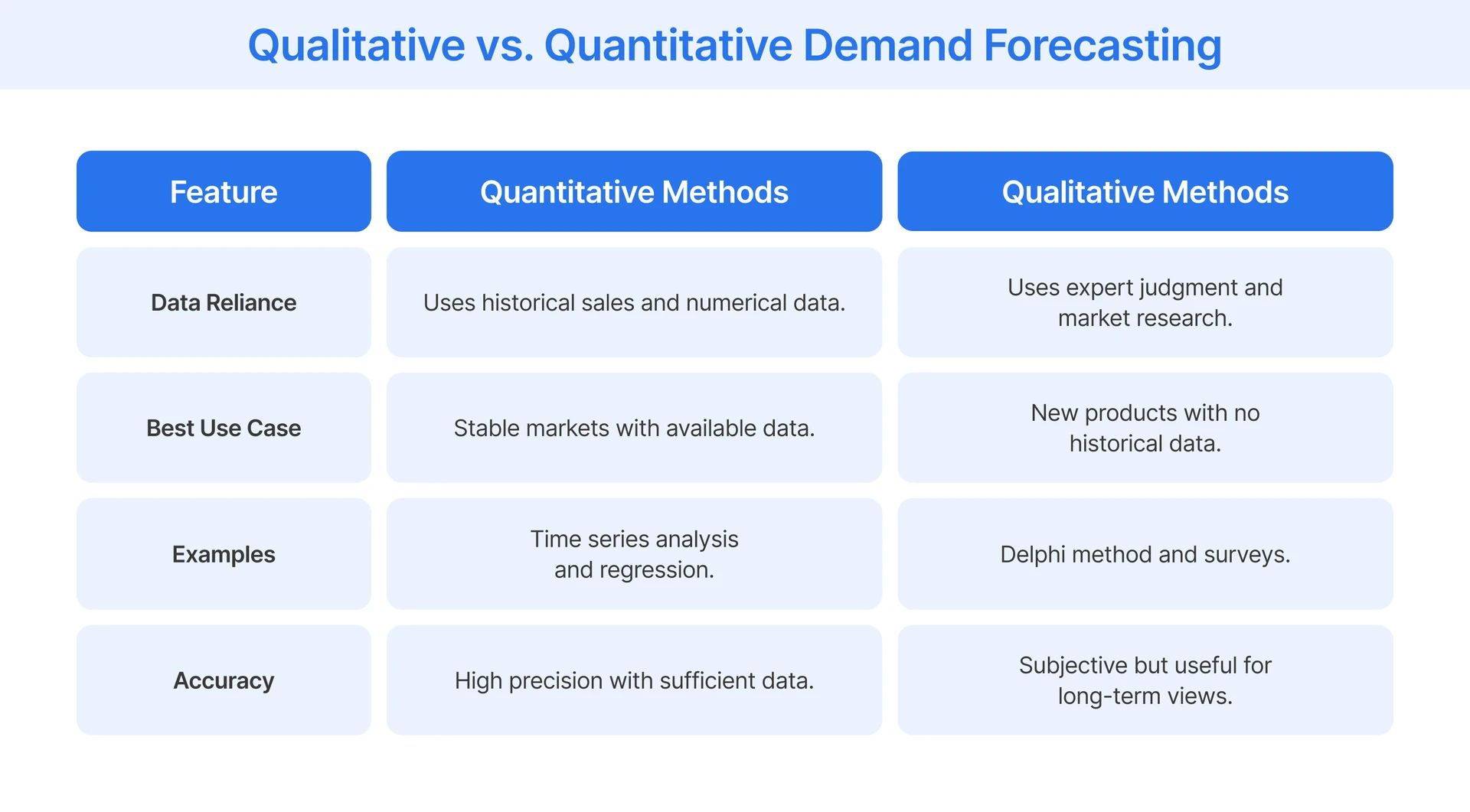

Quantitative forecasting relies on hard numbers and data sets, acting like a ‘math geek.’ It uses techniques such as ‘Time Series Analysis’ to predict future sales based on last year's data and ‘Regression Analysis’ to examine how economic conditions affect volume.

On the other hand, qualitative forecasting depends on expert opinions and intuition, much like a ‘people person.’ Strategies you can employ herein include ‘Market Research’ with customer groups, the ‘Delphi Method’ for expert consensus, or a ‘Sales Force Composite’ where sales teams provide estimates.

Understanding the differences between the two methods helps you select the best practices for your specific data availability and goals.

How to Forecast Demand Like a Pro?

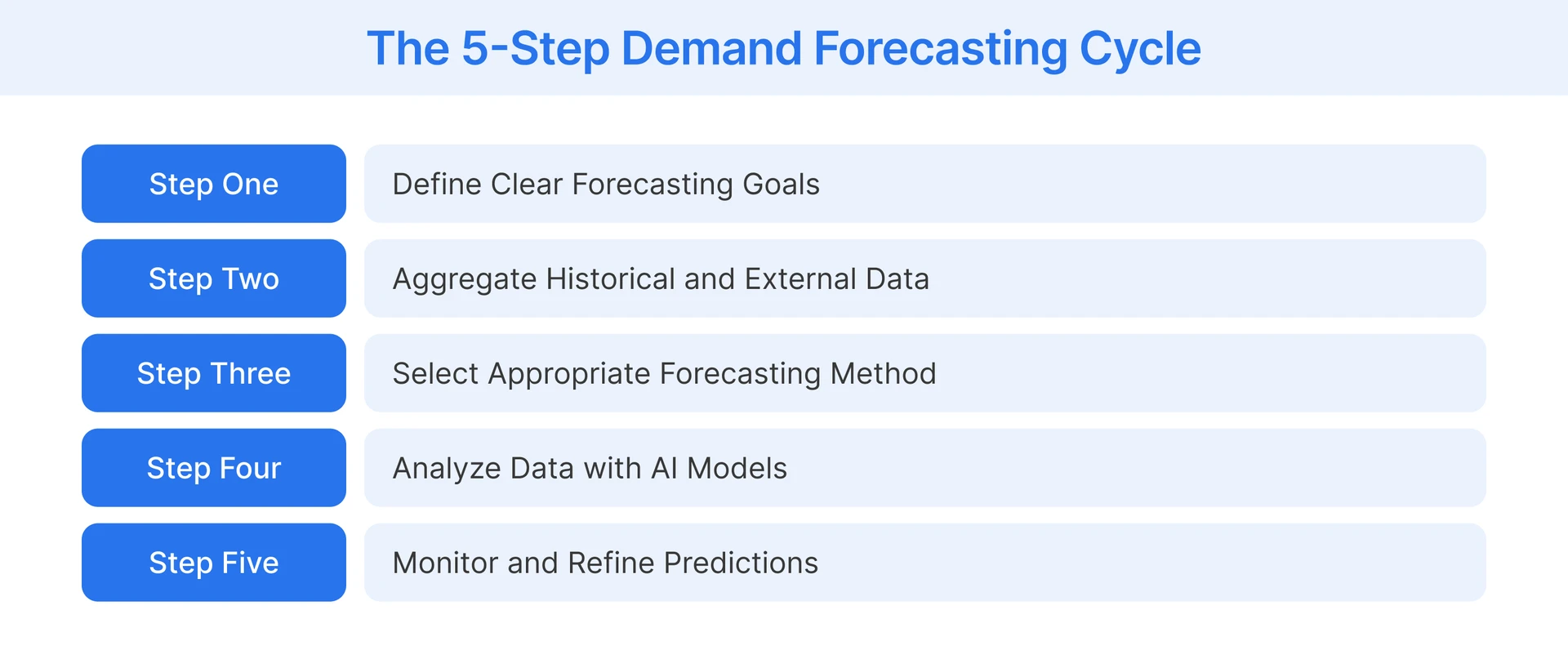

You must follow the following structured forecasting process to turn raw information into actionable intelligence:

Step 1 - Set Your Goals

Determine whether you are planning for the next month or the next five years. Short-term goals focus on immediate inventory management while long-term goals guide broader business planning. Defining your horizon early ensures you select the correct forecasting model for your specific needs.

Step 2 - Collect the Data:

Gather comprehensive sales data, competitor information, and details on external factors like weather patterns. You need clean data sources to ensure your forecasting model outputs reliable results. This step involves consolidating information from various channels to create a unified view of your supply chain.

Step 3 - Choose Your Method:

Pick the flavor that fits your available data and specific business context effectively. You might choose time series for established products or qualitative methods for a new launch. Small business owners often blend both approaches to account for market changes and seasonal fluctuations.

Step 4 - Crunch the Numbers:

Run the selected model using advanced analytics or artificial intelligence tools to generate your numbers. This stage is where machine learning algorithms analyze complex demand patterns to identify correlations. The goal is to produce demand forecasts that reflect reality as closely as possible.

Step 5 - Validate and Adjust:

Compare your forecast to actual performance and tweak the model to improve forecast accuracy. This is a living cycle where you continuously refine your approach based on new data points. Active demand forecasting requires constant monitoring to adapt to economic trends and consumer behavior shifts.

Forecasting With Flipkart Commerce Cloud

The retail landscape is unforgiving when you rely on manual spreadsheets or outdated methods to predict customer demand. Supply chain complexities and rapidly changing market trends make it impossible to guess accurately. You need intelligent tools to navigate economic conditions effectively.

We provide Flipkart Commerce Cloud to give you immediate access to our market-tested Inventory Management System. We empower you to automate demand planning and optimize your stock levels with precision. Our solution removes the guesswork from your resource allocation strategy.

We leverage advanced and scale-tested machine learning models to predict demand with pinpoint accuracy. Our system transforms your raw numbers into clear and valuable insights for decision-making. We help you anticipate seasonal fluctuations and adjust your inventory levels proactively.

Beyond simple predictions, we integrate this data with our Pricing Manager to drive real operational efficiency. We enable you to maximize profit margins and streamline supply chain management effortlessly, ensuring you always have the right product available at the right price.

FAQ

The four primary methods include qualitative forecasting, time series analysis, causal models, and simulation. Retailers often use a combination of these demand forecasting methods to account for market trends and data availability. Each method offers unique strengths for different business strategies.

Demand forecasting is the process of predicting future sales based on historical data and analysis. Demand planning is the broader process of using those forecasts to ensure you have the right supply. Planning involves the actual execution of inventory management and logistics.

The best way depends on your specific goals, the maturity of your product, and available data. Quantitative forecasting is ideal for established products with rich history, while qualitative methods suit new launches. Most successful retailers use a hybrid approach for accurate demand forecasts.

You should update your demand forecasts regularly to reflect real-time sales data and changing market conditions. High-velocity retail environments often require weekly updates to maintain optimal inventory levels. Regular updates ensure your supply chain remains agile and responsive to customer needs.