Table of Contents

- What is a Warehouse Management System?

- How Does a Warehouse Management System Transform Retail and E-commerce Fulfillment?

- What are the Key Functionalities of Warehouse Management Software?

- What are the Different Types of Warehouse Management Systems?

- What Benefits Can Retailers Gain from Implementing a Warehouse Management System?

- How Can E-commerce Businesses Choose the Right Warehouse Management System?

- How FCC Warehouse Management System Helps E-commerce Platforms?

What is a Warehouse Management System?

A Warehouse Management System (WMS) is a software application that enables retailers and e-commerce platforms to manage their daily warehouse operations optimally. This critical component of supply chain management provides real-time visibility into inventory and streamlines processes from inbound receiving to outbound shipping.

Key functionalities of a robust WMS include:

- Efficiently managing goods from arrival through the putaway process.

- Providing real-time insights into all inventory locations and movements.

- Optimizing order picking, packing, and fulfillment for rapid processing.

- Automating the generation of shipping documents and tracking information.

- Improving labor management through optimized task allocation and scheduling.

How Does a Warehouse Management System Transform Retail and E-commerce Fulfillment?

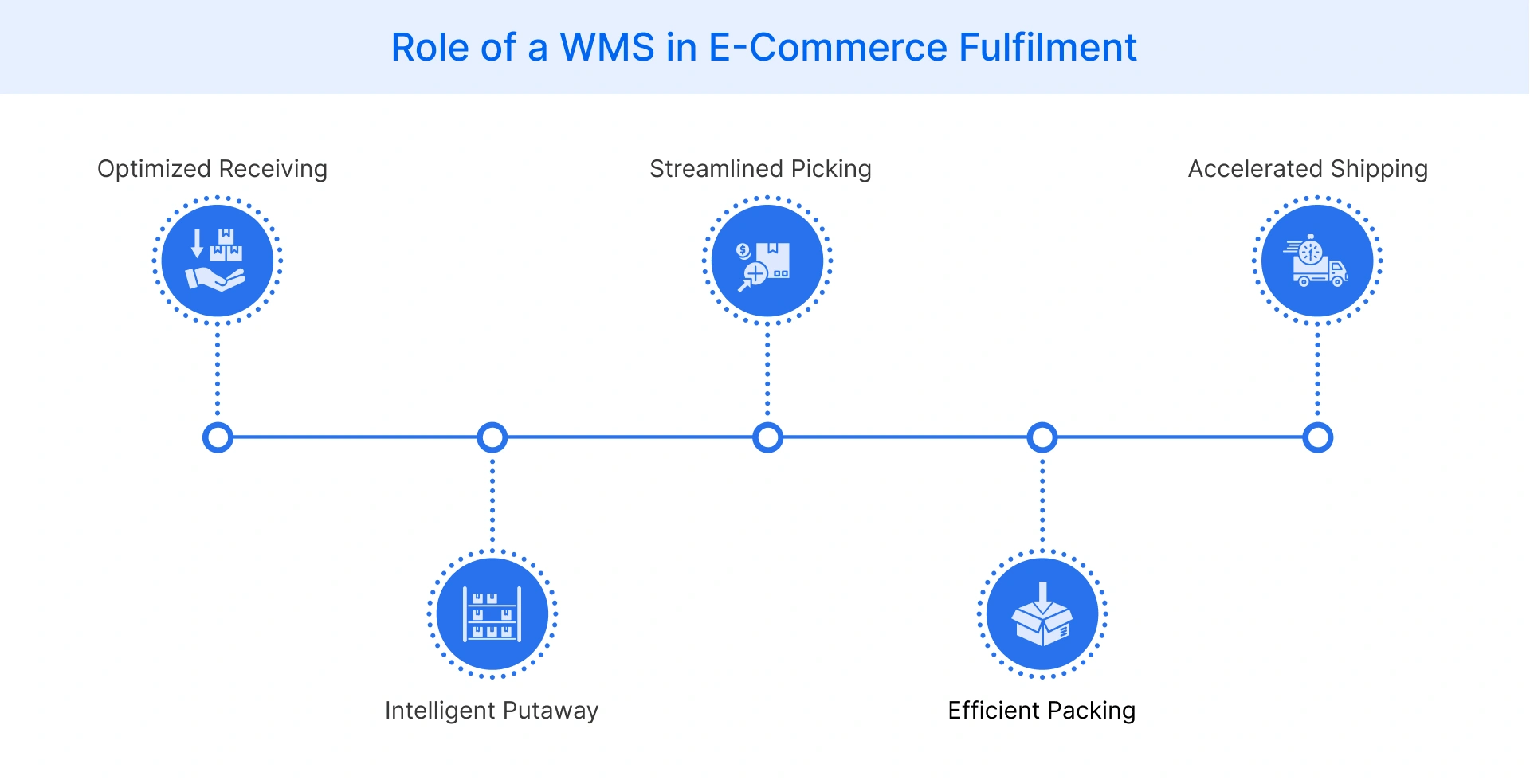

By centralizing operations, modern WMS solutions provide precise control over every inventory movement, thereby significantly improving operational efficiency and customer satisfaction. Let’s understand how it helps transform retail and e-commerce processes:

- Optimized Receiving: The system streamlines the inbound process, accurately receiving goods and quickly moving them into storage. This efficiency reduces dock-to-stock times, making inventory available faster for customer orders.

- Intelligent Putaway: This system utilizes guided putaway strategies, placing items in optimal warehouse locations. This maximizes space utilization and significantly reduces the time spent searching for products.

- Streamlined Picking: It achieves higher picking accuracy and speed by directing associates along the most efficient routes. This minimizes errors and accelerates the preparation of orders for dispatch.

- Efficient Packing: The system standardizes packing procedures, ensuring products are securely prepared for shipment. This process optimizes material use and prepares packages for timely dispatch.

- Accelerated Shipping: It automates the generation of shipping labels and carrier assignments, ensuring timely dispatches. This integration streamlines supply chain logistics and enables real-time tracking for customers.

What are the Key Functionalities of Warehouse Management Software?

A Warehouse Management System covers several critical functionalities that work together to create an efficient operational ecosystem for retail and e-commerce businesses.

- Inventory Tracking: This functionality provides real-time visibility into all stock, including its location within the warehouse. It helps retailers monitor inventory levels, prevent stockouts, and manage product traceability efficiently.

- Labor Management: The system optimizes your workforce by tracking productivity and forecasting staffing needs. It helps e-commerce platforms create schedules and assign tasks, reducing unproductive travel time within the facility.

- Yard Management: This feature oversees the movement of vehicles in the yard, from arrival to departure. It aids in organizing trailers and optimizing dock assignments, minimizing delays at loading docks.

- Dock Scheduling: It allows you to schedule inbound and outbound shipments precisely, avoiding congestion. This functionality ensures that dock doors are utilized efficiently, improving overall throughput.

- Reporting and Analytics: The system automatically collects operational data and generates insightful reports. This enables data-driven decision-making, allowing retailers to identify trends and areas for ongoing improvement.

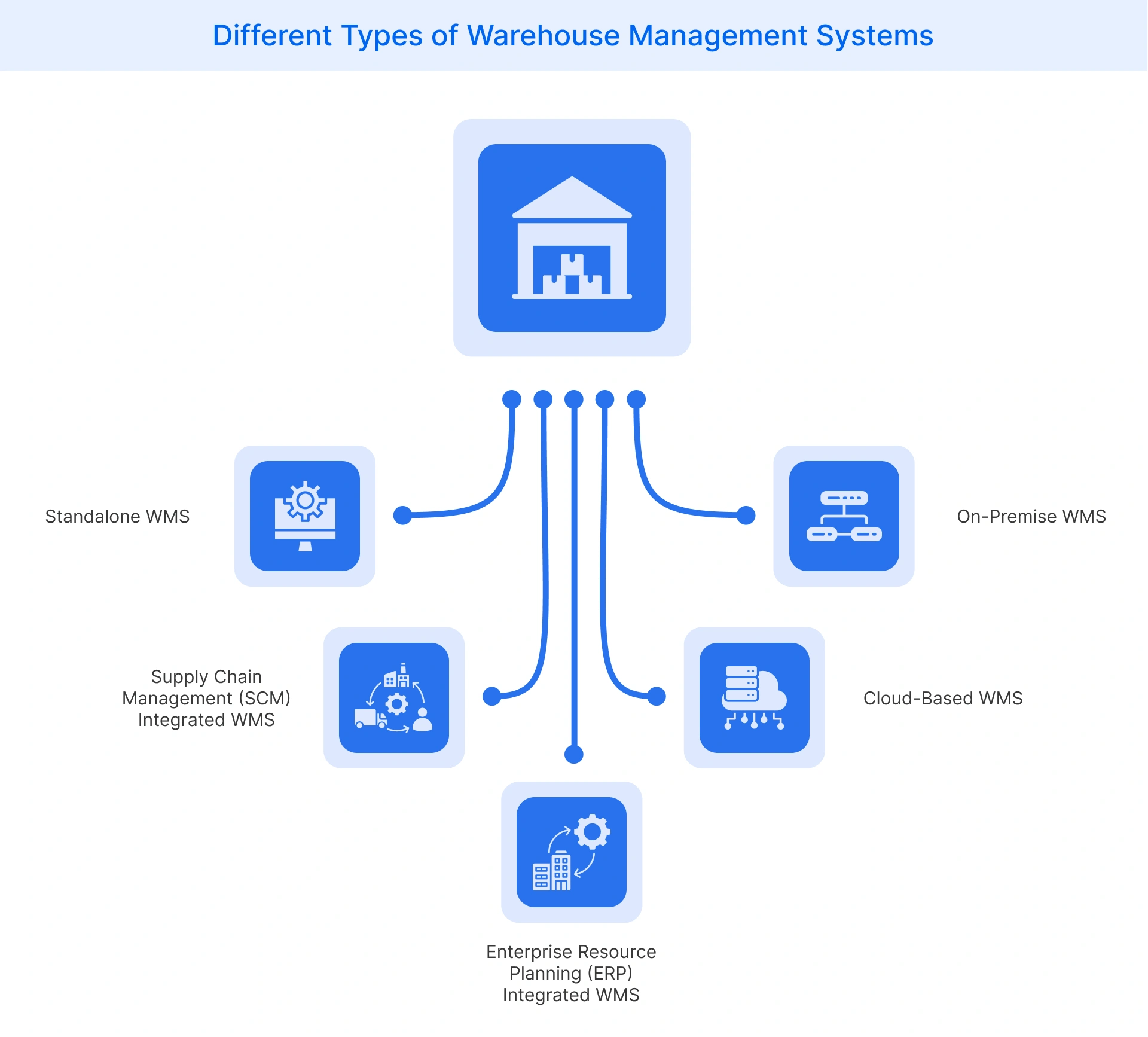

What are the Different Types of Warehouse Management Systems?

Warehouse control systems come in various configurations, each designed to address specific retail business requirements and operational complexities. Here are the different types of WMS systems that warehouse managers and supply chain leaders can use to accurately monitor the movement of goods.

Standalone WMS

Standalone WMS software functions independently from other business software, focusing exclusively on warehouse processes. These specialized solutions offer in-depth functionality for complex storage environments, customizable workflows, and advanced inventory management capabilities, all without requiring integration with broader business systems. Such WMS systems are ideal for retailers with multiple warehouses or distribution centers.

Supply Chain Management (SCM) Integrated WMS

SCM-integrated warehouse software functions as a component within comprehensive supply chain platforms. These solutions connect warehouse operations with procurement, demand planning, and transportation management, providing visibility across the entire product journey. Retailers gain enhanced forecasting abilities, coordinated inventory allocation, and streamlined communication between supply chain partners.

Enterprise Resource Planning (ERP) Integrated WMS

ERP-integrated WMS operates as a module within enterprise-wide business platforms. These unified solutions enable seamless information flow between warehouse operations and other business functions, including accounting, sales, purchasing, and customer service. This integration eliminates data silos, provides consistent financial reporting, and facilitates accurate order-to-cash processes.

Cloud-Based WMS

Cloud-based warehouse execution systems operate on remote servers accessed via the internet, eliminating the need for extensive on-site IT infrastructure. These solutions offer rapid implementation, automatic updates, subscription-based pricing models, and the ability to access inventory data securely from anywhere. E-commerce businesses particularly benefit from the scalability during seasonal peaks.

On-Premise WMS

On-premise WMS resides on the company’s own servers and infrastructure within their physical location. This traditional deployment model gives businesses complete control over their data security, system customizations, and integration capabilities. E-commerce platforms with specific compliance requirements or unique business needs often prefer this approach despite higher initial investment.

What Benefits Can Retailers Gain from Implementing a Warehouse Management System?

An efficient Warehouse Management System offers retailers significant strategic advantages, optimizing supply chain operations and enhancing overall business performance. The numerous benefits of a warehouse management system directly contribute to improved efficiency and customer satisfaction.

- Improved Inventory Accuracy: Real-time visibility into stock levels and locations significantly reduces discrepancies. This accuracy prevents costly stockouts and overstocking, leading to better sales forecasting and inventory turns for retailers.

- Enhanced Customer Satisfaction: Faster, more accurate order fulfillment processes directly translate to happier customers. Reduced shipping errors and quicker delivery times build consumer trust and encourage repeat business for your e-commerce platform.

- Reduced Operational Costs: Optimizing warehouse space, labor, and processes minimizes waste and inefficiencies. This leads to substantial savings in labor, storage space, and shipping expenses, boosting your retail profitability significantly.

- Increased Productivity: Automation and streamlined workflows empower warehouse staff to complete tasks faster. This efficiency allows for higher order volumes with existing resources, improving throughput and operational capacity for your business.

- Data-Driven Decision-Making: Comprehensive reporting and analytics provide actionable insights into warehouse performance. This data helps you identify bottlenecks, optimize strategies, and make informed decisions for continuous operational improvement.

How Can E-commerce Businesses Choose the Right Warehouse Management System?

Selecting the ideal Warehouse Management System requires careful evaluation of both current operational requirements and future growth objectives for e-commerce businesses.

- Business Scale Assessment: Evaluate order volume, SKU count, number of warehouses, and staff size to determine the appropriate WMS complexity level, ensuring the solution provides adequate functionality without unnecessary features.

- Integration Capabilities: Prioritize systems that offer robust APIs and pre-built connectors for e-commerce platforms, marketplaces, shipping carriers, and accounting software, enabling the creation of a unified technology ecosystem without manual data transfers.

- Scalability Potential: Choose a Warehouse Management System designed to accommodate business growth through flexible user licensing, capacity expansion options, and the ability to add functionality modules as operational needs evolve.

- Implementation Timeline: Consider available IT resources, staff training requirements, and business seasonality when evaluating implementation timeframes. Cloud-based solutions typically offer faster deployment than on-premises alternatives.

- Total Cost Evaluation: Calculate complete ownership costs, including software licensing, implementation services, hardware requirements, integration development, ongoing maintenance, and potential productivity gains when comparing WMS options.

How does the FCC Warehouse Management System Help E-commerce Platforms?

FCC Warehouse Management System, part of Flipkart Commerce Cloud’s comprehensive supply chain management suite, delivers enterprise-grade inventory and fulfillment capabilities specifically designed for modern e-commerce operations. This scale-tested platform supports billions of daily transactions, enabling retailers to achieve robust performance even during peak demand periods.

The system offers intuitive, self-serve functionality that empowers businesses to execute sophisticated warehouse strategies without extensive technical expertise. FCC’s WMS streamlines critical processes, including inventory tracking, order routing, labor management, and returns processing through an interface that prioritizes operational efficiency and data accessibility across multiple warehouse locations.

Integration flexibility stands as a core advantage of the FCC’s Warehouse Management System, enabling seamless connections with existing technology stacks and third-party platforms. This interoperability eliminates data silos between order management, inventory, shipping, and marketplace channels, creating a unified operational ecosystem that supports omnichannel retail strategies while reducing implementation complexity and time-to-value.

FAQ

A Warehouse Management System (WMS) optimizes entire warehouse operations, from receiving to shipping, overseeing physical movement and processes. An Inventory Management System primarily focuses on tracking stock levels and locations. While WMS includes inventory control, its scope extends to workflow optimization, labor, and space utilization within the facility.

Small and medium e-commerce businesses gain significant benefits from a Warehouse Management System. It enhances order accuracy, improves fulfillment speed, and optimizes inventory control, leading to reduced operational costs. Scalable WMS solutions help these businesses manage growth, boost productivity, and elevate customer satisfaction without extensive infrastructure.

A Warehouse Management System efficiently manages seasonal retail demand by offering scalable operations and optimizing resource allocation. It facilitates rapid adjustments in labor and space utilization, ensuring smooth processing of increased order volumes. This system's flexibility helps businesses maintain high service levels during peak periods, avoiding bottlenecks.

Yes, a Warehouse Management System is typically designed to integrate seamlessly with various existing e-commerce platforms. This crucial capability ensures smooth data flow between sales channels and warehouse operations, automating order processing, inventory updates, and shipping information. Integration streamlines fulfillment and enhances overall supply chain visibility for businesses.