Table of Contents

- What is a Stock Keeping Unit?

- Key Components of a Stock Keeping Unit

- Importance of Stock Keeping Units in Retail Management

- SKUs vs. Other Product Identifiers

- How to Create Effective SKUs?

- Benefits of Using SKUs

- Challenges in SKU Management

- Conclusion

What is a Stock Keeping Unit (SKU)?

A Stock Keeping Unit (SKU) is a distinctive identifier assigned to various products in a company’s inventory. It is a crucial tool in retail and e-commerce for tracking stock levels, sales, and overall inventory management. Unlike Universal Product Codes (UPCs), SKUs are for internal use and specific to each business, allowing for customized categorization and tracking. This level of detail is particularly beneficial for businesses with large or diverse product catalogs helps with easy organization of data to prevent stockouts and overstock situations.

SKUs typically consist of alphanumeric codes representing various product attributes, such as size, color, style, brand name, and price point. This granular identification enables retailers to monitor individual item performance, streamline order fulfillment, and make data-driven decisions about restocking and discontinuation based on real-time sales trends.

Key Components of a Stock Keeping Unit

Here are the essential elements that make up an effective stock-keeping unit:

- Alphanumeric Code: This unique code combines letters and numbers to create a distinct identifier for each type of product in your inventory. For example, ‘BL-SM-001’ could represent a blue, small-sized item with the product number 001. A well-designed SKU generator can assist in maintaining consistency when creating your own SKUs.

- Product Category or Department: Often, the first characters of an SKU indicate the product’s category or department. This allows for quick identification and sorting of items. For instance, ‘EL’ might stand for electronics, while ‘CL’ could represent clothing.

- Attribute Indicators: SKUs frequently include shorthand notations for specific product attributes. These could denote size (S, M, L), color (BLK, WHT, RED), or material (CTN for cotton, LTH for leather). These indicators provide instant information about the product’s characteristics.

- Vendor or Manufacturer Code: If you stock physical products from multiple suppliers, incorporating a vendor code into your SKU code can be beneficial. This addition helps track the source of each item and manage supplier-specific inventory.

- Sequential Numbering: The final component of many SKUs is a unique number that distinguishes different products within the same category or with similar attributes. This ensures that even highly similar items have distinct identifiers.

Importance of Stock Keeping Unit in Retail Management

Stock-keeping units play a pivotal role in modern retail management, serving as the backbone of an efficient inventory management system and data-driven decision-making.

SKUs enable the precise tracking of individual products, allowing you to monitor stock levels in real-time and prevent costly stockouts or overstock situations. This improved visibility empowers you to optimize the inventory, ensuring that popular items are always available while minimizing investment in slow-moving products.

SKUs facilitate streamlined order fulfillment processes. With unique identifiers for each product variant, your staff can quickly locate and pick items, reducing errors and improving overall efficiency. This enhanced accuracy translates to faster shipping times and increased customer satisfaction.

The data generated by SKU-based systems provides invaluable insights for strategic decision-making. You can analyze sales patterns, identify trending product recommendations, and make informed choices about product mix and pricing strategies. This data-driven approach allows you to adapt swiftly to market demands and maximize profitability.

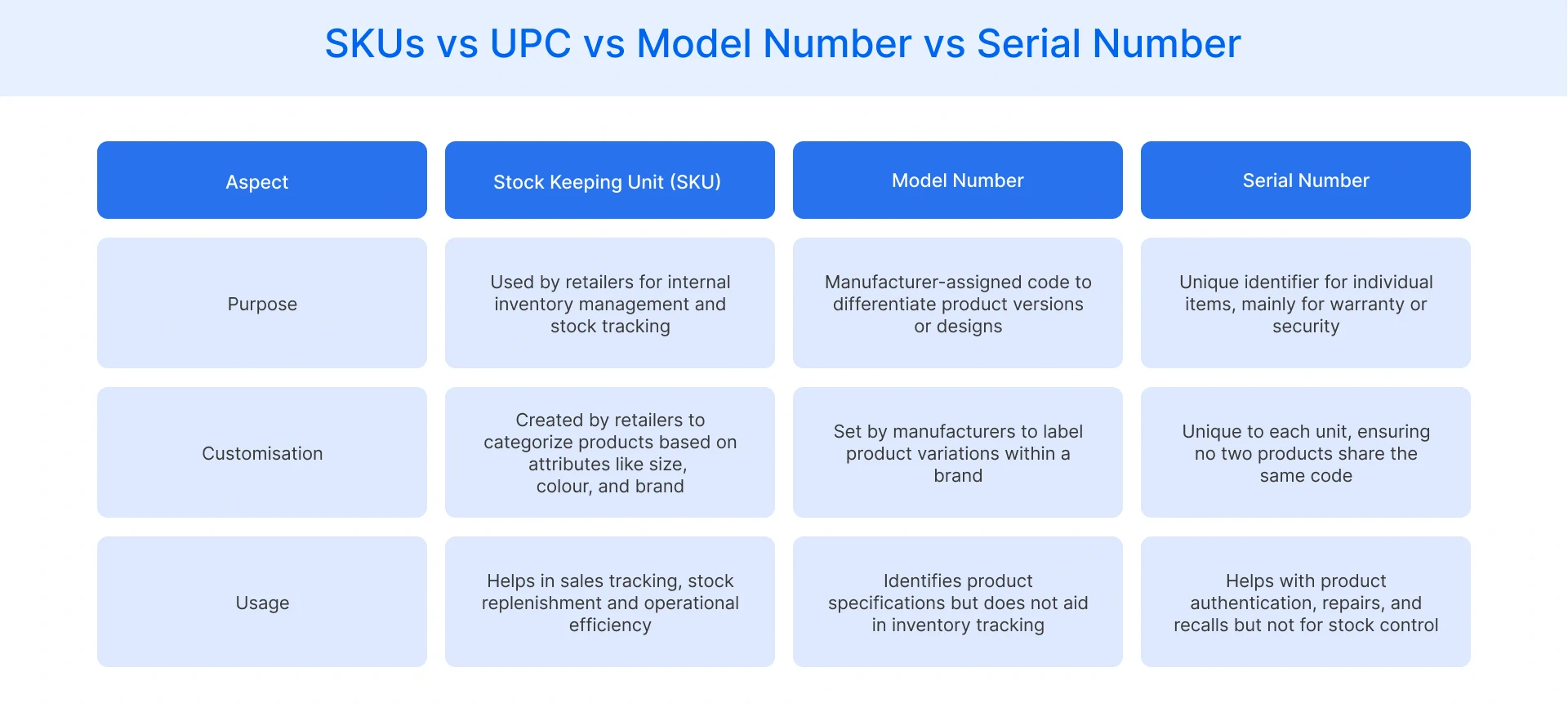

SKUs vs. Other Product Identifiers

Understanding the differences between SKUs and other identifiers can help you leverage each type effectively in retail operations.

Universal Product Codes are standardized, 12-digit numbers used across multiple retailers. Unlike SKUs, UPC barcodes are assigned by the Global Standards Organization and remain consistent regardless of the seller. They are used mainly for point-of-sale scanning and external product identification.

Model numbers, assigned by manufacturers, identify specific product designs or versions. These remain constant across retailers but don’t typically account for variations like color or size. Model numbers are useful for warranty claims and customer support but lack the granularity of SKUs.

Serial numbers uniquely identify individual units of a product, often used for high-value items or electronics. They are crucial for tracking specific items through the supply chain and for warranty purposes but are too specific for general inventory management.

SKUs, in contrast, are retailer-specific and offer the flexibility to encode various product features. This makes them ideal for internal inventory tracking, order fulfillment, and data analysis.

How to Create Effective SKUs?

By following these guidelines, you can create new SKUs that work seamlessly for your business:

Establish a Consistent Format

Develop a standardized structure that includes a set number of characters and follows a logical order of information. For example, you might use a 10-character SKU number where the first two characters represent the department, the next three indicate the product type, followed by two for color and three for size.

Use Meaningful Prefixes

Start each SKU with letters or numbers that represent key product categories or departments. This approach allows for quick identification and sorting of items. For instance, ‘EL’ could denote electronics, ‘AP’ for apparel, or ‘HG’ for home goods. These prefixes create an intuitive system that your team can easily understand and navigate.

Incorporate Product Attributes

Include relevant product details within the SKU to provide instant insights about the item. For example, you might use ‘BL’ for blue, ‘SM’ for small, or ‘WL’ for wool. Encoding these attributes enables faster decision-making and reduces the likelihood of errors during order fulfillment or inventory counts.

Avoid Confusing Characters

Steer clear of characters that can be easily misread or confused. Avoid using ‘0’ and ‘O’ or ‘1’ and ‘I’ interchangeably, as these can lead to errors in data entry or product identification. Instead, opt for clear, distinct characters that minimize the risk of misinterpretation.

Keep it Simple and Scalable

Design your SKU system to be easily understood by employees and flexible enough to accommodate future product additions or changes. Avoid overly complex codes that require extensive training or documentation. A simple, intuitive system will facilitate quicker adoption and reduce errors.

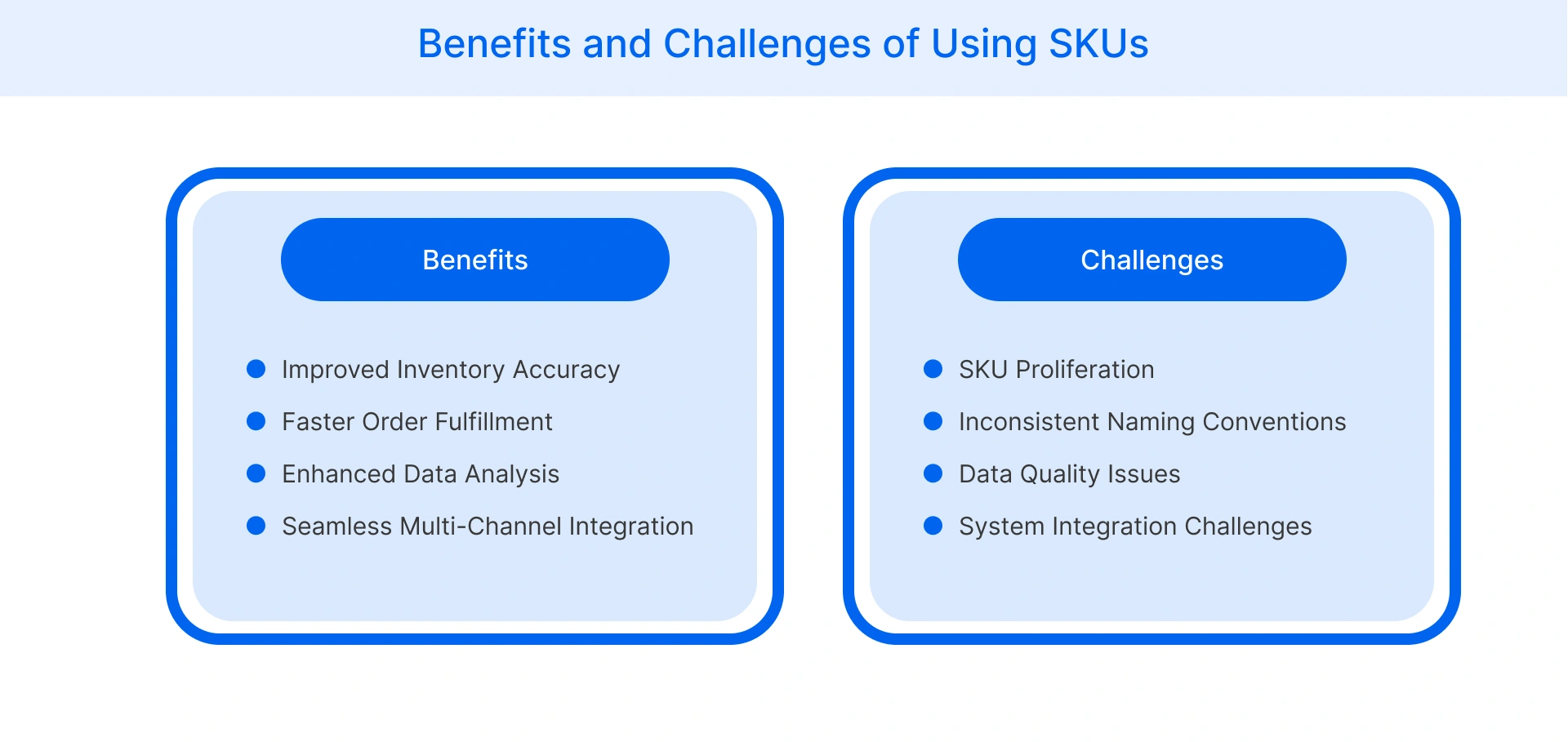

Benefits of Using SKUs

Implementing a SKU system offers numerous advantages that can significantly enhance retail operations:

- Improved Inventory Accuracy: SKUs provide a precise method for tracking each product variant in a retail store inventory. This detail allows companies to maintain accurate stock counts, reducing discrepancies between recorded inventory and actual stock levels. SKUs can also help identify slow-moving items, prevent overstocking, and ensure that popular products remain available.

- Faster Order Fulfillment: With unique identifiers for each product, the staff can quickly locate and pick items for orders. This efficiency translates to faster processing times, reduced errors in order fulfillment, and ultimately, improved customer satisfaction. SKUs can also facilitate automated product fulfillment centers, further streamlining retail operations.

- Enhanced Data Analysis: By analyzing SKU-level sales data, businesses can identify trends, understand customer preferences, and make informed choices about product mix and pricing. This data-driven approach allows companies to optimize their inventory investment and maximize profitability.

- Seamless Multi-Channel Integration: In the modern omnichannel retail environment, SKUs play a crucial role in maintaining consistency across various sales platforms. Whether a customer is shopping in-store, online, or through a mobile app, SKUs ensure accurate product information and inventory levels are displayed across all channels.

Challenges in SKU Management

While stock-keeping units offer numerous benefits, managing them effectively can present certain challenges.

- SKU Proliferation: As the product range expands, companies may have an overwhelming number of SKUs. This can lead to increased complexity in inventory management and potentially higher carrying costs. To address this, it is crucial to regularly review the SKU list, discontinue underperforming items, and consolidate similar products where possible.

- Inconsistent Naming Conventions: Without a standardized approach to creating SKUs, inconsistencies can creep in, especially in businesses with multiple users or departments managing inventory. Implement clear guidelines for SKU creation and conduct regular audits to ensure adherence to these standards.

- Data Quality Issues: Inaccurate or incomplete SKU data can lead to errors in inventory management and financial reporting. To maintain high-quality SKU information, invest in robust data management systems and processes. Regular data cleansing and validation exercises can help identify and correct discrepancies.

- System Integration Challenges: As businesses grow and adopt new technologies, integrating SKU data across different systems (e.g., POS, e-commerce platforms, and warehouse management systems) can be complex. For smoother operations, choose inventory management solutions from Flipkart Commerce Cloud that offer seamless integration capabilities.

Conclusion

A well-structured Stock Keeping Unit (SKU) system is essential for efficient inventory management, accurate sales tracking, and seamless product categorization. Implementing such a system can significantly enhance operational efficiency, from streamlining order fulfillment to optimizing inventory levels. SKUs also provide invaluable data for strategic decision-making, enabling swift responses to market trends and customer preferences.

FAQ

Companies should review their SKU system regularly, ideally quarterly or semi-annually. This allows for timely updates to accommodate new product lines, discontinuations, or changes in product attributes. Regular reviews help maintain system efficiency and ensure the SKU structure remains aligned with current inventory management needs.

No, each SKU should be unique within a company's inventory system. Sharing SKUs across multiple products would defeat the purpose of using SKUs for precise inventory tracking and management. Each product variant, even if only slightly different (e.g., size or color), should have its own unique SKU to ensure accurate stock counts and order fulfillment.

SKUs are retailer-specific identifiers for inventory management purposes, while model numbers are manufacturer-assigned and remain consistent across retailers. SKUs often include more detailed product information, such as size or color, whereas model numbers typically represent a product line or design.