Table of Contents

- What Is an Inventory Cycle Count?

- Inventory Cycle Count vs. Physical Inventory: What’s the Difference?

- Benefits of Inventory Cycle Counting

- Popular Inventory Cycle Counting Methods (How to Actually Do It)

- Best Practices for Inventory Cycle Count

- Automate Your Inventory Cycle Count

What is Inventory Cycle Count?

An inventory cycle count is an auditing procedure where retailers count a small subset of inventory on a specific day. This inventory management strategy allows businesses to check stock levels continuously throughout the year rather than stopping everything for an annual audit. It ensures records match physical reality without disrupting daily operations.

- It eliminates the need to shut down the entire store or warehouse for a comprehensive physical inventory count during business hours.

- Retailers can detect theft or inventory loss much faster because high value items are counted more frequently.

- Teams can ensure higher accuracy by correcting small errors immediately before they spiral into major inventory discrepancies.

- Financial reporting becomes more precise because accounting teams have real-time visibility into actual inventory versus recorded quantities.

- Warehouse staff experience less fatigue since they count manageable batches of inventory items daily.

Inventory Cycle Count vs. Physical Inventory: What’s the Difference?

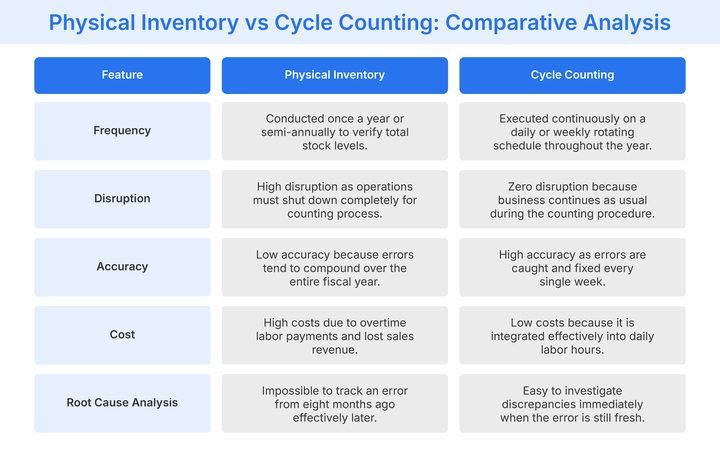

Understanding the difference between these two auditing methods helps you choose the right path for your supply chain.

While physical counting requires a complete freeze of operations for a full count of your total inventory, cycle counting offers a continuous approach. It integrates the auditing process into daily tasks without stopping sales or shipping.

If you rely solely on physical inventory, you are looking at massive downtime and high labor costs. In contrast, cycle count inventory methods allow you to measure inventory variance, the difference between what your system says and what is actually on the shelf, in bite-sized pieces.

What are the Benefits of Inventory Cycle Counting?

Implementing a robust cycle counting process transforms how businesses manage stock levels and operational efficiency within the warehouse. As a retailer, you can get several advantages over competitors who rely solely on annual physical counts.

-

No More Downtime: You never have to close your doors. This continuous process allows staff to verify inventory levels during slow periods. You maintain full operational capacity while ensuring records remain accurate.

-

Better Cash Flow: Accurate data prevents you from overstocking items that tie up capital. You make smarter purchasing decisions based on the actual inventory value, releasing working capital for other areas.

-

Improved Customer Service: Nothing kills a relationship faster than cancelling an order because an item was "out of stock" despite what the website said. By reducing inventory errors, you fulfill orders reliably.

-

Catch Discrepancies Early: Staff can identify data entry errors or misplaced items as soon as they occur. This immediacy allows managers to fix the root cause while the trail is fresh.

Popular Inventory Cycle Counting Methods (How to Actually Do It)

Retailers use different strategies to determine which number of items to count and when. You should select a method that aligns with your number of SKUs and product value.

ABC Analysis (The Gold Standard)

ABC cycle counting categorizes inventory based on value to prioritize counting efforts on high-impact items. Under the ABC method, staff count ‘A’ items frequently because they represent the highest value or sales volume. ‘B’ items are counted less often, while ‘C’ items with the lowest value are counted even less frequently by the team.

Random Sample Counting

Managers select a small group of items or a random batch to count each day. This racndom sample cycle counting technique prevents warehouse staff from predicting which items will be counted next (which is great for security). It acts as a spot check for your overall inventory control.

Best Practices for Inventory Cycle Count

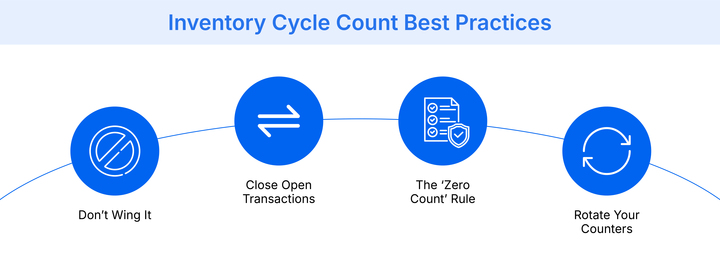

Adopting the right habits ensures the cycle counting program delivers accurate results without overwhelming the warehouse team. You must establish clear protocols to maintain consistency and data integrity throughout the auditing process.

-

Don’t Wing It: Retailers need a documented plan that specifies exactly when counts occur and who is responsible for them. Random inventory counting without a schedule leads to missed SKUs and duplicated efforts. A structured schedule ensures that every item gets counted at least once within a specific timeframe for accuracy.

-

Leverage Technology: Ditch the clipboard. Use mobile devices and barcode scanners to update the system in real time. This reduces manual inventory data entry errors significantly.

-

Close Open Transactions: You must ensure all shipping and receiving activities for the target items are completed before the count begins. Counting items while inventory is still moving leads to phantom discrepancies and inaccurate records. Staff should process all outstanding paperwork and pause movement for the specific bin location being counted.

-

The ‘Zero Count’ Rule: Teams should treat a zero count with the same seriousness as a discrepancy in the inventory records. Finding an empty bin when the system expects stock indicates a process failure or theft issue. You must investigate why the item is missing to correct the underlying operational problem immediately.

-

Rotate Your Counters: Assigning different staff members to count various sections prevents complacency and reduces the risk of internal theft. Familiarity often breeds oversight, so fresh eyes are more likely to catch labeling errors. It ensures higher data integrity when managers regularly shuffle counting responsibilities among the warehouse team members.

Automate Your Inventory Cycle Count

Manual inventory tracking often relies on spreadsheets or paper lists that are prone to human error. Retailers need automated systems to ensure data accuracy and speed up the reconciliation process. Implementing technology reduces the labor burden and provides real-time insights into stock levels without stopping daily operations.

At Flipkart Commerce Cloud (FCC), we understand that maintaining precise inventory records is critical for scaling your retail business effectively. Our solutions are designed to bridge the gap between physical stock and digital records. FCC integrates seamlessly with your current infrastructure to modernize how you handle inventory auditing and management.

Our Inventory Management System automates the scheduling of cycle counts based on your specific business rules. We use intelligent algorithms to prioritize high-value items through dynamic ABC analysis. You gain full visibility into inventory movements across all locations to prevent stockouts and minimize shrinkage risks efficiently.

We ensure your physical counts instantly sync with online channels through our Omni-channel Order Management System. This real-time update prevents overselling by keeping your available-to-promise inventory accurate. Our advanced analytics further help you identify operational bottlenecks and optimize your counting frequency for maximum efficiency.

FAQ

The frequency depends entirely on inventory volume and the value of products. We recommend counting high-value ‘A’ items daily or weekly to ensure tight control over critical assets. Retailers can schedule lower-value ‘C’ items for quarterly or semi-annual counts to balance accuracy with labor costs effectively for the business.

Yes, effectively implemented cycle counting programs can eliminate the need for annual physical inventories for most retailers. Businesses must demonstrate consistent inventory accuracy to auditors to qualify for this operational benefit. This shift allows you to maintain continuous operations without the costly shutdowns associated with traditional comprehensive physical counts.

Most industry experts consider an inventory accuracy rate of 95 percent or higher to be the benchmark for success. Retailers should aim to reach this level to ensure customer satisfaction and efficient order fulfillment. Continually falling below this threshold indicates underlying process issues that require immediate operational attention.

Staff must verify the count a second time to rule out simple counting errors. If the discrepancy persists, managers should adjust the inventory record to match the physical count immediately. Afterward, the team needs to investigate the root cause to prevent the specific error from recurring.